Machining Technology

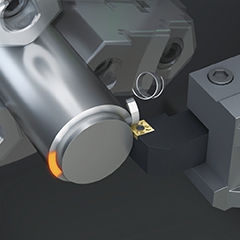

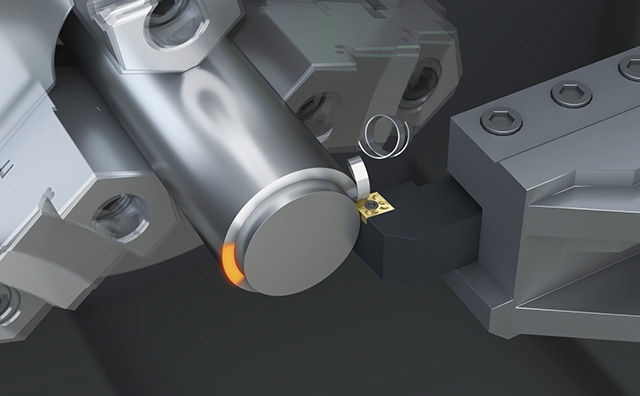

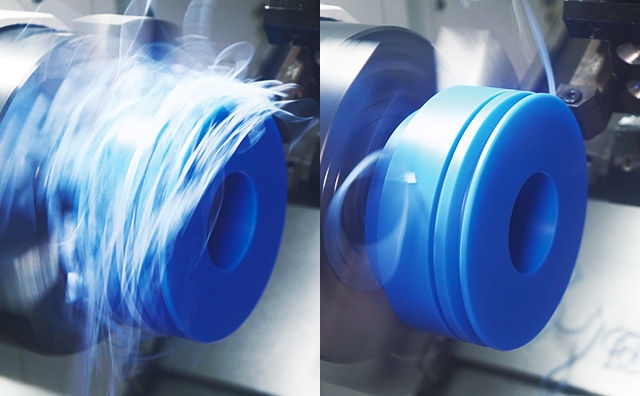

SMOOTH OSCILLATION CUTTING

Smooth Oscillation Cutting is a machining function of the MAZATROL CNC. This function can break chips that are tough-to-cut.

- Reduction of machining troubles caused by chips

- Eliminates the need for workers to dispose of chips, improving the operating rate of automatic operation

- Supported CNC systems: |MAZATROL SmoothAi

- MAZATROL SmoothG

- MAZATROL SmoothEz

*: For compatible models, please contact Mazak.

High usability

Reduces entanglement of chips in workpieces and tools

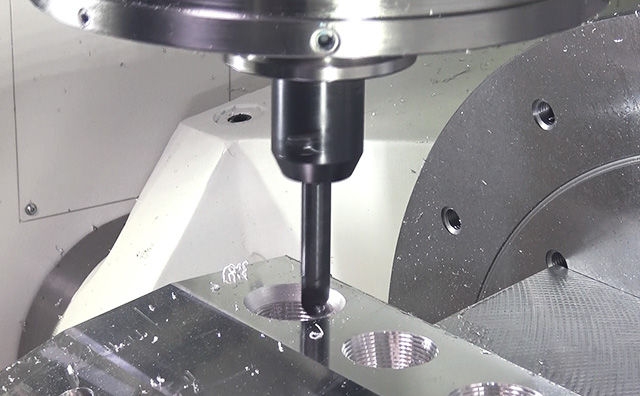

- The turning spindle and feed axis are synchronized to provide non-cutting areas during cutting, allowing chips to be cut.

- Supports a wide range of materials including resin, iron, stainless steel, and aluminum

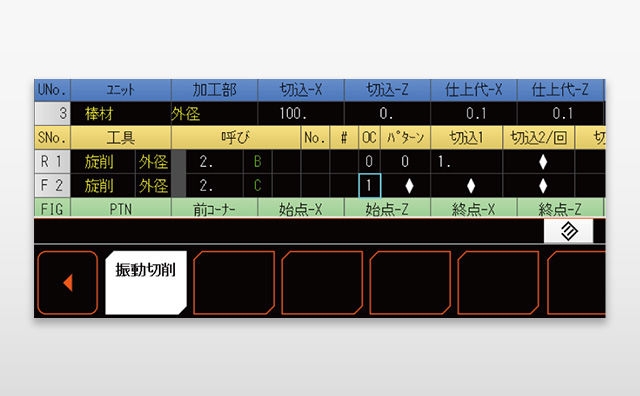

Simplified programming

- Easy option switching; enter 1 for Smooth Oscillation Cutting, or 0 to not use it.

- No need for lengthy, complicated setup

- Oscillation settings can be automatically determined with G code programming

Supports a wide range of machining

- Inside / outside diameter machining, face-grooving

- Surface machining, inside / outside diameter grooving

- Taper machining (X-axis / Z-axis)

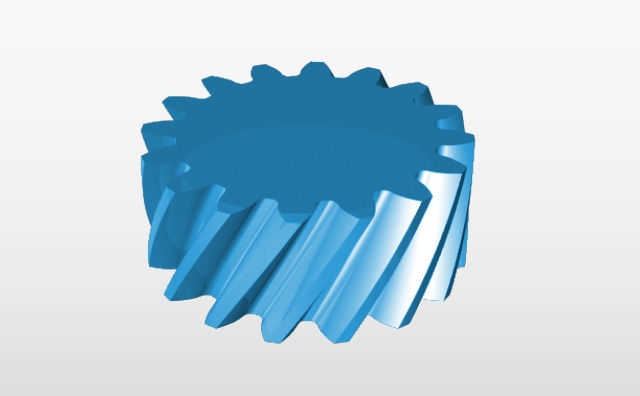

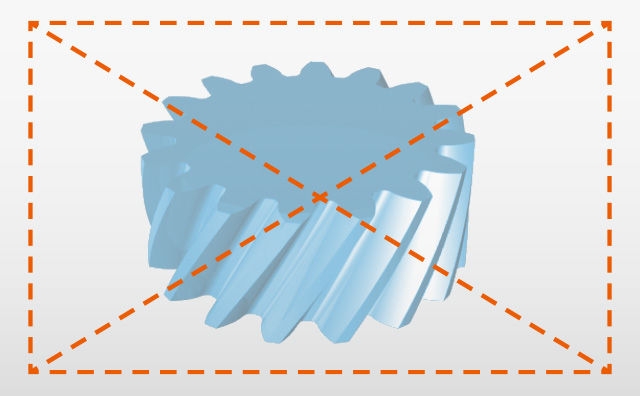

SMOOTH GEAR CUTTING

By using SMOOTH GEAR CUTTING, you can easily create gear cutting programs and perform cutting. Various information is made visible, making settings and adjustments easy. This allows you to check the status, performance and adjustments, improving productivity.

- Supported CNC systems: |MAZATROL SmoothAi

MAZATROL SmoothG

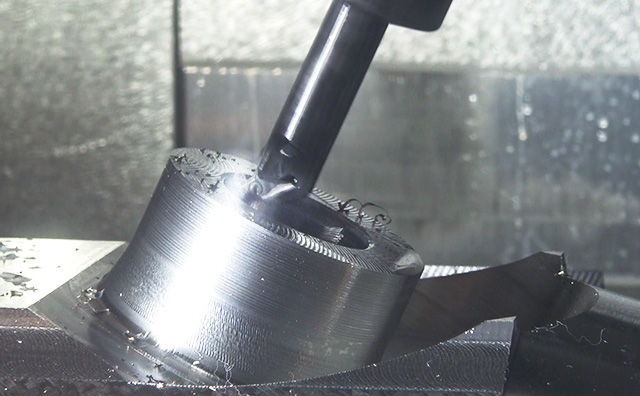

Gear machining can be easily performed using conversational numerical input and commercially available end mills.

Conversational numerical input enables highly efficient and precise machining of external and internal gears .

By constantly synchronizing the tool axis and workpiece axis during acceleration and deceleration, optimal gear hobbing is possible from the rough machining process to finishing.

Comparison with conventional processing methods

Without SMOOTH GEAR MILLING (optional)

- step-1

- step-2

- step-3

- step-4

With SMOOTH GEAR MILLING (optional)

Just the input of the necessary information and machining conditions into the CNC system is needed to begin machining.

- step-1

- step-2

- step-3

- step-4

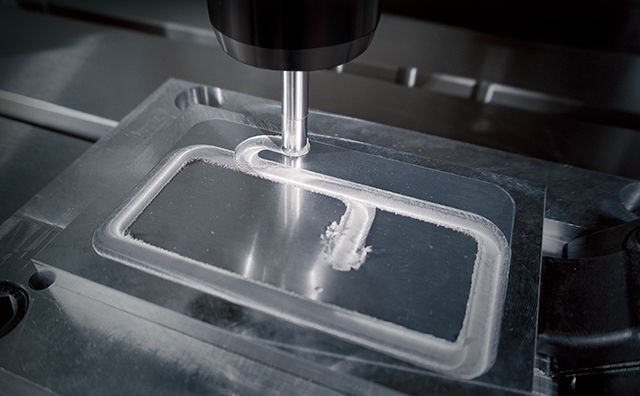

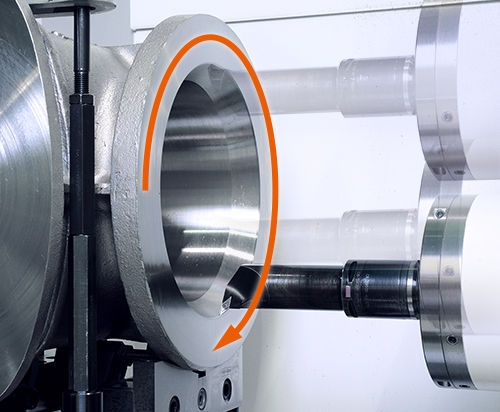

ORBIT MACHINING

ORBIT MACHINING can integrate the processes of turning, which require special fixtures and special purpose machines.

This is a very effective method for machining valve sealing surfaces / grooves, tapered holes, etc.

- A single tool can be used to perform turning of various diameters

- It is possible to process inside diameter larger than the tool diameter.

- Supported CNC systems: |MAZATROL SmoothAi

MAZATROL SmoothG

MAZATROL SmoothEz

Added G code for orbit cutting

Achieve high-quality machining

- The machining program is similar to conventional turning centers machining, with cross-sectional shapes set as straight lines, tapers, and arcs.

- Constant surface speed control is possible, enabling high-quality machining even with tapered shapes.

Orbit machining on a slanted surface with a multi-tasking machine

- Orbit machining is possible on a slanted surface with a tilted B axis

Programming Support

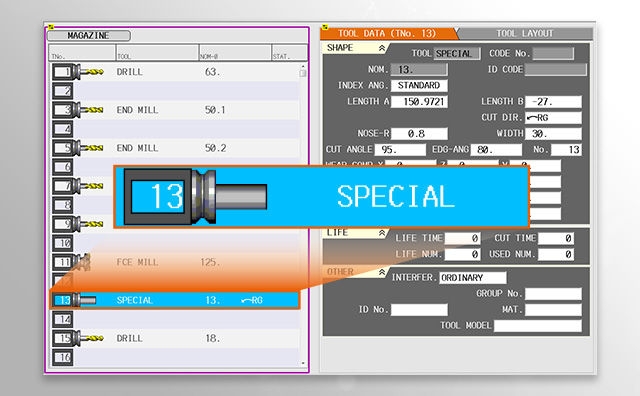

Tool registration

- Turning tools can be registered on the machining center's tool data screen.

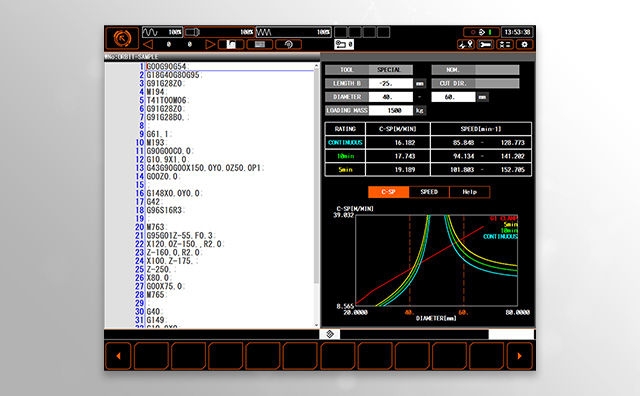

Orbit machining assist

- The orbital machining conditions (peripheral speed [IPM], revolution speed [RPM]) can be easily calculated by inputting a few items such as tool information and machining diameter.

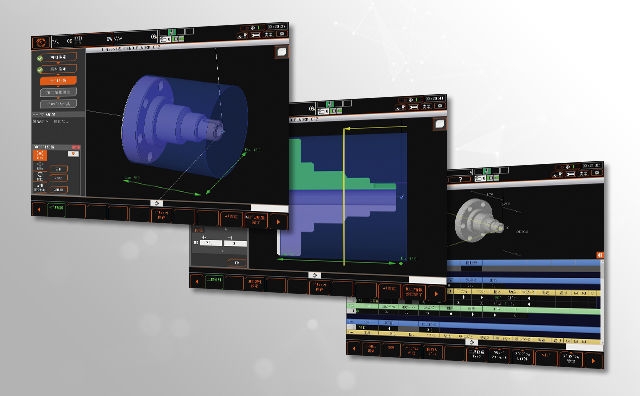

Smooth Machining Configuration

Set up machining parameters

This function allows you to easily tune the complex parameters related to "machining time (speed)", "finished surface (smoothness)", and "shape (accuracy)" according to multiple conditions. This includes conditions such as; what the workpiece is, machining method, the priority of machining time / shape accuracy, rough machining, and finishing.