| Tool shank (standard) | CAT No.40 |

| Max. spindle speed | 15000 min-1 (rpm) |

| Table size | 133.86" × 20.08" |

Vertical Machining Centers

SVC

- Equipped with BT40 high-speed, high-power spindle for high-speed machining of non-ferrous materials

- Traveling column and X-axis linear motor enables high-speed feedrate of long stroke.

- Fixed long table provides exceptional versatility, such as long workpiece machining, multiple workpiece setups, 2-pallet changer type operation

- Equipped with touch screen CNC system MAZATROL SmoothG

Highly efficient machining of long workpieces

Equipped with CAT No.40 high-speed, high-power spindle for high-speed machining of non-ferrous materials

The standard spindle is a high-speed, high power spindle with a revolution speed of 15000 rpm and an output of 22 kW (30 HP). 25000 rpm HSK-A63 spindle is also available as an option.

Linear motor provides high speed, high accuracy machining

X-axis linear motor

High-speed feedrate with rapid traverse of 4724 IPM and cutting feed of 1181 IPM. Machining is performed quickly with high positioning accuracy, even with long strokes. It improves productivity by reducing idling time and positioning time for long workpieces and multiple-workpiece machining.

Fixed long table provides exceptional versatility

Long table provides exceptional versatility, such as long workpiece machining, multiple workpiece setups, 2-pallet changer type operation. Large, long workpieces can be machined - even those that overhang the large stationary table.

Table size

2000L/120 : 133.86" × 20.08"

2000L/200 : 212.6" × 20.08"

Equipped with touch screen CNC system MAZATROL SmoothG

MAZATROL SmoothG is a CNC system with a graphical user interface and touch screen for easy operation. It is equipped with a variety of functions that help reduce programming time and improve machining efficiency.

Screen operation while checking workpieces inside the machine

Operation touch panel can be tilted to the optimum position for any operator's height to ensure ease of operation.

Support for programming and machining

MAZATROL interactive programming uses conversational language and it is easy to make / edit programs by inputting data on workpiece drawings in response to questions displayed on the operation screen. Even inexperienced operators can create programs quickly.

Machining features including cycle time, finished surface and machining shape can be adjusted by slider switches on the display according to material requirements and machining methods.

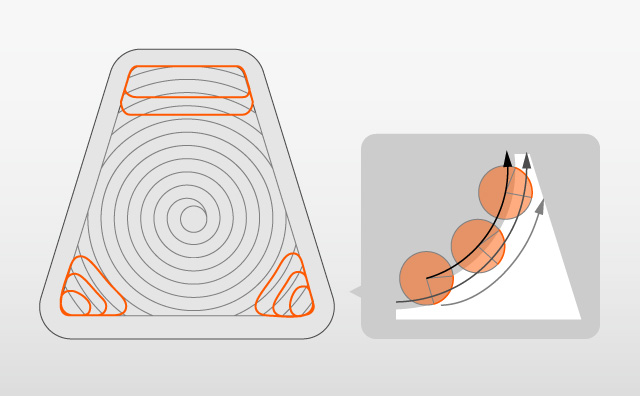

This function maintains a constant angle of engagement between the cutter and material to create a high efficiency tool path during pocket milling. It reduces chip load variation, extends tool life and allows tools to be used to their full potential.