| Chuck size | 15" to 21" |

| Max. machining diameter | Φ32.28″ |

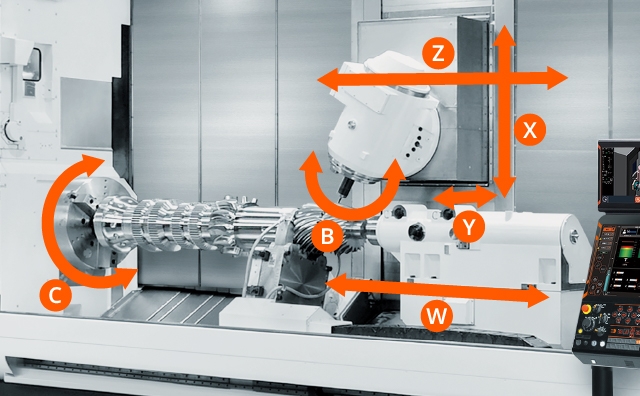

| Y-axis travel | 19.69″ |

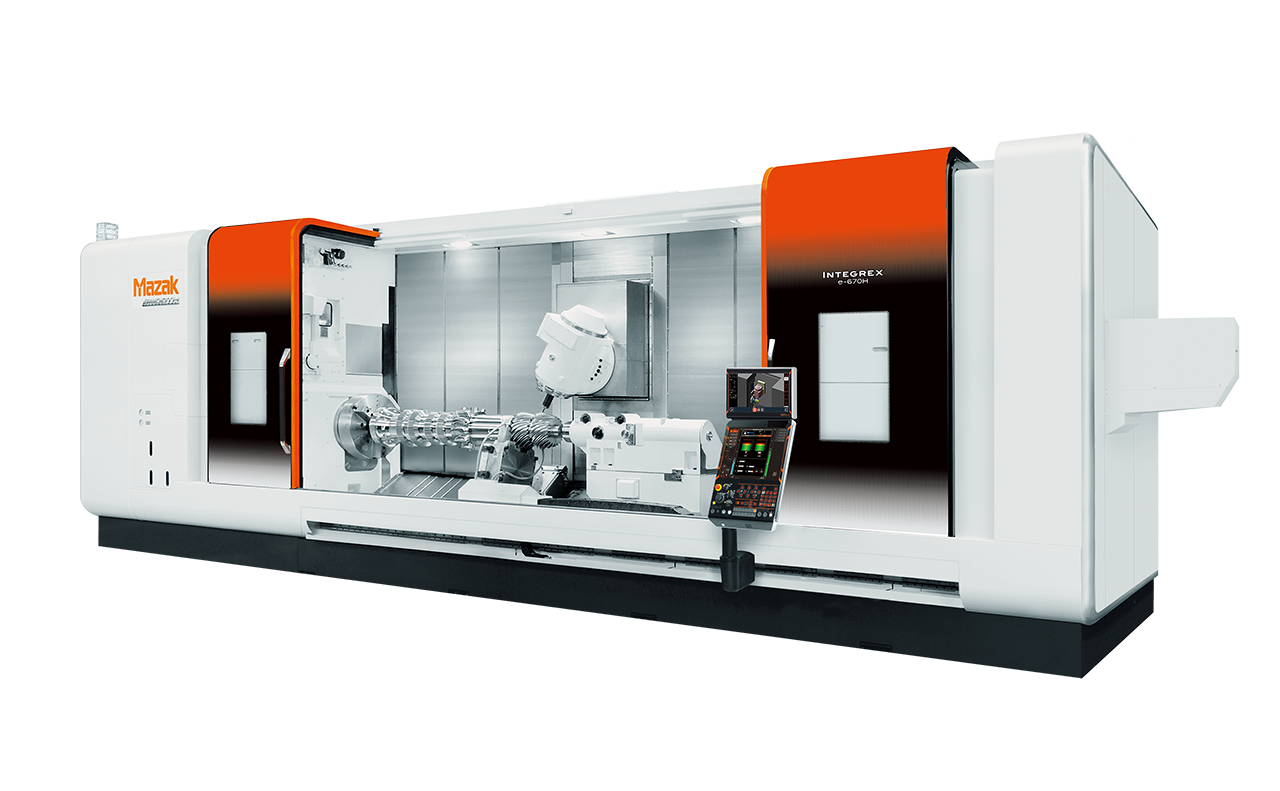

Multi-Tasking Machines

INTEGREX e-H

- Large swing and Y-axis stroke for large workpieces

- Wide variety of optional equipment for process integration and enhanced versatility

- MAZATROL SmoothAi drives innovation for even higher productivity

Combining years of trust and technical expertise

Orthogonal design provides large operation area and high-accuracy machining

Powerful milling performance equivalent to that of machining centers. Highly rigid structure and wide variety of features for high-accuracy

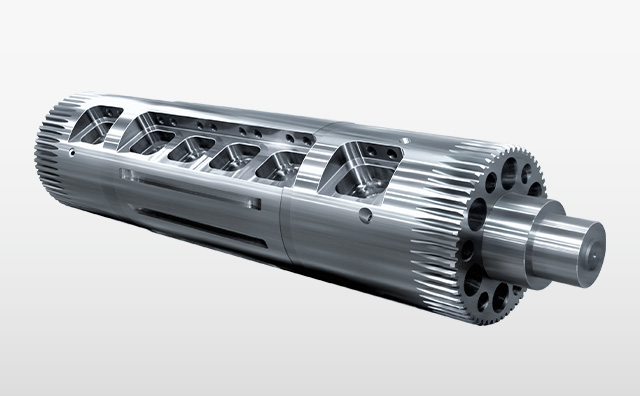

Enhanced productivity through process integration

Reducing processes by one-eighth and lead times by one-fifth

The INTEGREX e-H series completes the entire process from raw material input to final machining with just one machine. Many benefits can be expected, including a significant reduction in production lead time, high accuracy due to fewer setup processes, cost savings in terms of fixtures and equipment, reduced machine installation space, and energy efficiency.

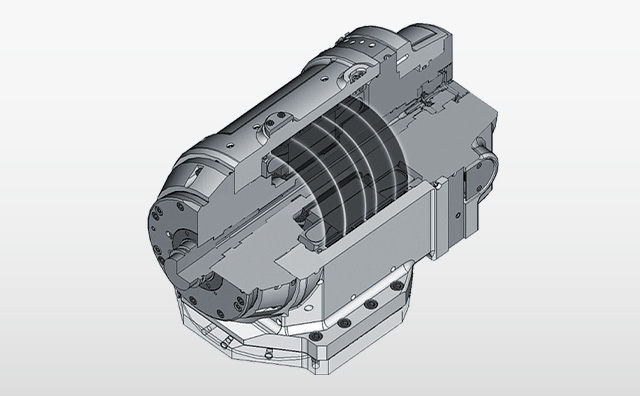

Powerful milling spindle for faster cycle times

Built-in motor spindle

A built-in motor spindle is adopted. Vibration is minimized during high acceleration/deceleration to ensure exceptional roundness and surface roughness.

Spindle temperature control

Temperature-controlled cooling oil is circulated around the spindle bearings and headstock to minimize thermal displacement of the spindle due to heat generation allowing high machining accuracy to be maintained.

Large machining area

The milling spindle with an automatic tool changer has minimum tool interference. The same tool can be used vertically, horizontally, and at any angle, enabling a variety of machining operations with fewer tools. It has a large range of motion to accommodate all types of machining.

Process integration and expansion of machining performance

Long boring bar system

Effective for the deep machining of inner diameters of large workpieces

- Max. tool length: 39.37″, 59.06″ (6000 U/8000 U)*

- Tools can be stored in the dedicated stocker

e-500H:2 pcs, e-670H:3 pcs, e-800H:4 pcs - Tool head can be changed automatically

- *| ATC max. length: 39.37″ (e-670H, e-800H)

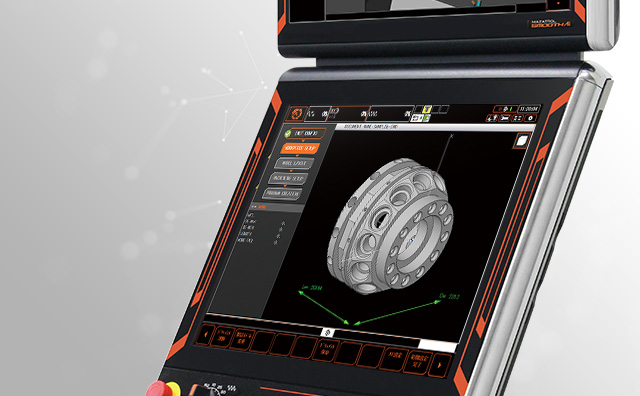

CNC system MAZATROL SmoothAi

Innovative MAZATROL CNC system for higher productivity

MAZATROL SmoothAi provides unsurpassed productivity through even faster and higher precision control while elevating your production with AI and digital twin technology and advanced automation capabilities.

SOLID MAZATROL (Automatic programming)

MAZATROL programs are automatically generated from 3D CAD data. AI learns machining know-how from previously generated programs, automatically calculates the machining process, and generate the optimal program.

CUTTING ADVISOR

Machining simulation and visualization of the machining process based on the accumulated machining results helps optimize cutting conditions.