| Spindle bore | Φ2.99" |

| Chuck size | 8″ |

| Max. machining diameter | Φ12.6" |

| Max. machining length | 33.86" |

CNC Turning Centers

HQR NEO

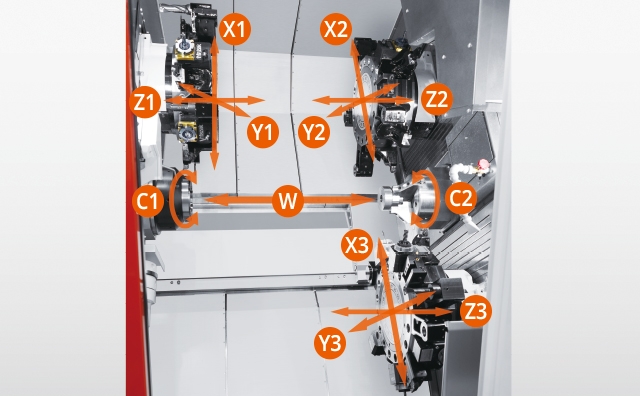

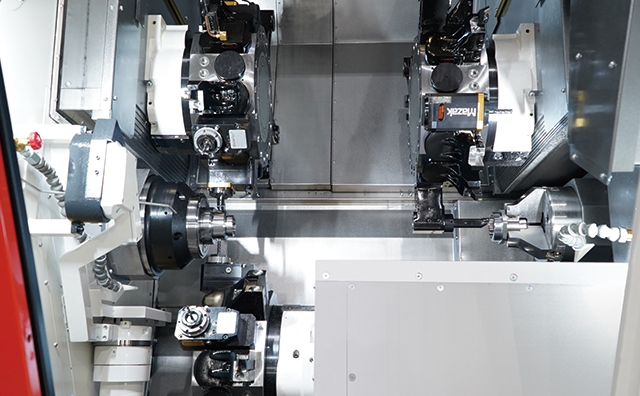

- 3 turret / 2 spindle machine construction for faster cycle times

- Bar work capacity up to Φ4.02" (option)

- Automation system for various applications from chuck to shaft workpiece

- The CNC system MAZATROL SmoothG3 for highly efficient machining with 3 turret

Machine construction for a significant reduction in cycle time

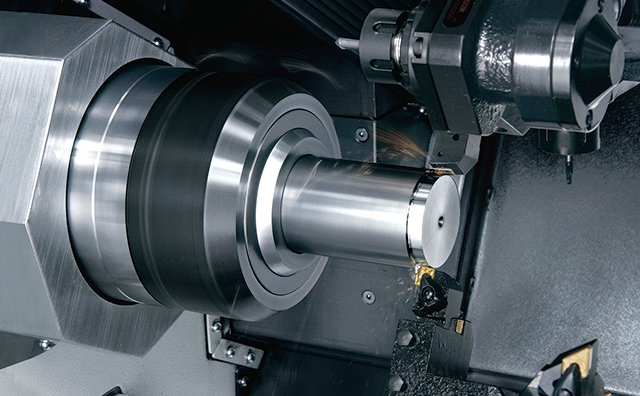

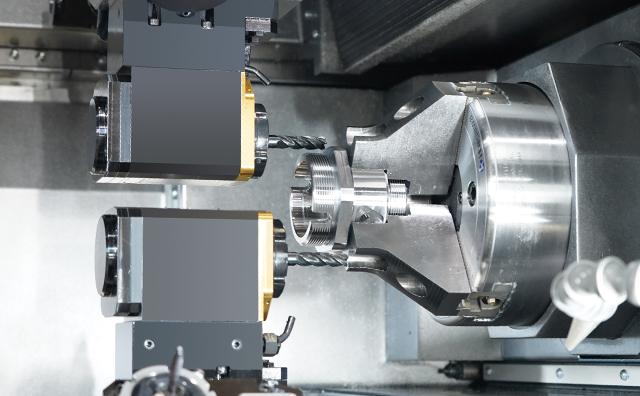

The unique 3 turret / 2 spindle machine structure performs simultaneous machining of two workpieces while maintaining balanced cutting using upper and lower turrets.

In workpieces where there is a difference in machining amounts between the first and second operations, our machine achieves significant productivity improvement even compared to 2 turret / 2 spindle CNC turning center.

Bar work capacity

Since both the main spindle and second spindle have large spindle bores, a wide range of bars can be machined.

| Machine model | Main spindle | Second spindle |

| HQR-200/3 NEO | Φ2.56" | Φ2.56" |

| Φ4.02" * | Φ2.56" | |

| HQR-250/3 NEO | Φ3.15" | Φ2.56" |

| Φ3.15" * |

*: Optional

Pursue even higher productivity through automation

A variety of automation equipment such as bar feeders, workpiece unloaders and robots are optionally available support long-term automatic operation.

Bar feeder and workpiece unloader

Effective operation from bar material to finished workpiece. By using a workpiece unloader instead of the auto parts catcher, the workpiece is removed from the machine without damaging the high-quality finished surface.

- Step 1

- Step 2

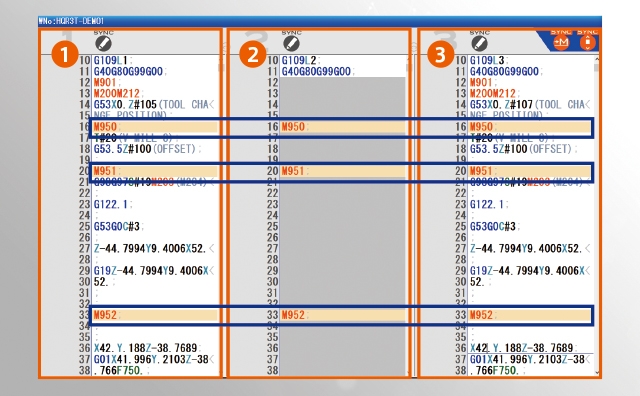

CNC system MAZATROL SmoothG3

Simultaneous 4-axis CNC system

- Screen design that takes advantage of touch operation speeds up task such as programming and editing.

The dedicated 3 turret screen supports the complex machining.

- Complex movements of the three turrets are supported by various interference check functions to ensure safe operation.

Interface for improved usability

Large touch screen for intuitive operation

Highly efficient machining with 3 turret dedicated display and support functions

The display divided into three columns makes it easy to confirm the operation of each turret. The EIA/ISO programming screen displays the waiting command positions side by side, enabling intuitive and easy program editing.

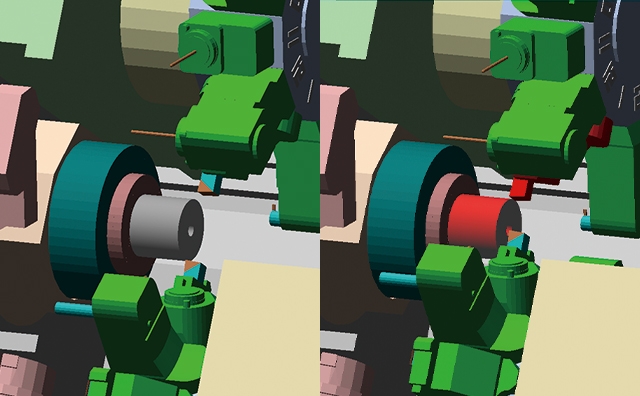

Various program check functions

Program checks are also difficult on 3-turret machines because of the complexity of turret movements, which makes it difficult to maintain synchronization of the individual turrets.

These functions support program checking without disrupting the synchronization of the turrets.

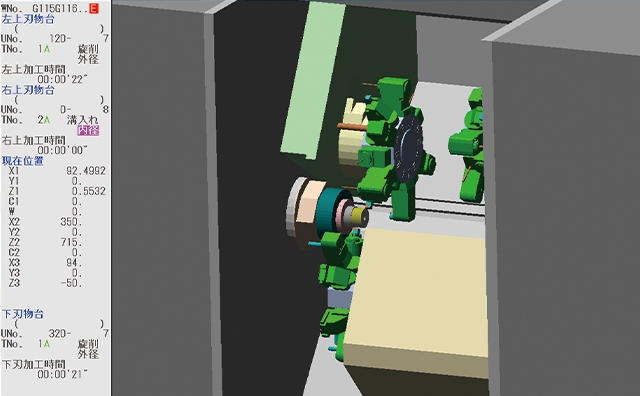

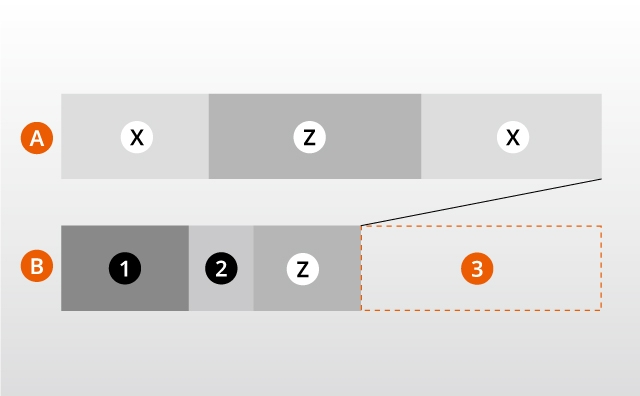

Virtual Machining

Accurate simulation under the same operating environment as the machine enables us to check the machining shape and interference in advance.

This enables highly productive operations from the first production piece.

Safety Shield

Even when axes are moved manually during setup work, the 3D model on the NC screen checks for interference and alerts the operator to prevent machine interference.

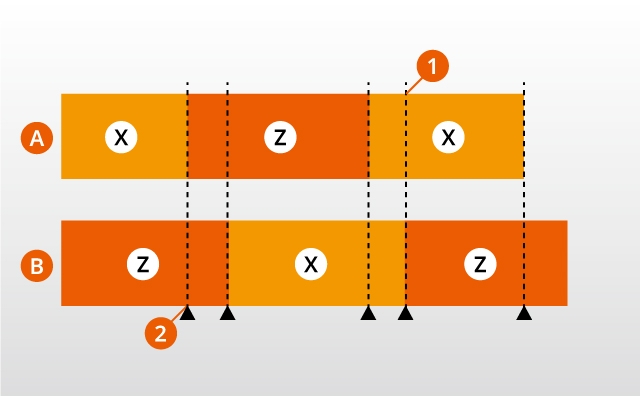

Inter-grid single block operation

When one turret completes a process, all turrets in operation stop simultaneously, even if the end of the block differs for each turret.

This inter-grid single block operation ensures the synchronization between turrets, preventing interference and increasing downtime caused by program misalignment.

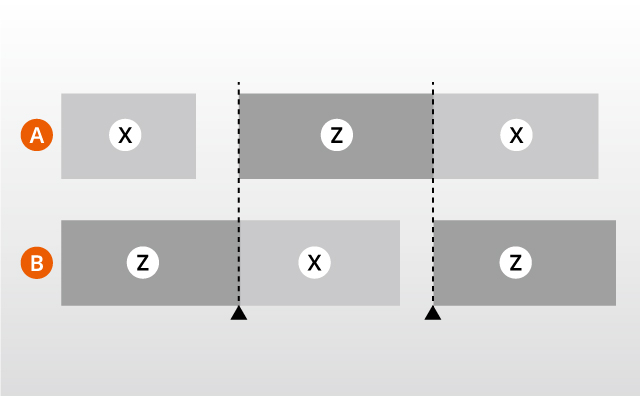

With Inter-grid single block operation

A: Turret A

B: Turret B

1: When turret B X-axis feed reaches ▲, turret A also stops.

2: When turret A X-axis feed reaches ▲, turret B also stops.

▲: Operation stop

Without Inter-grid single block operation

A: Turret A

B: Turret B

▲: Operation stop

Override synchronized operation

Override, which allows adjustment of program processing time, is reflected not only in the operating time of the turrets but also in the standby time, thus enabling program operation without disrupting synchronization between turrets. This allows for high-accuracy interference checks.

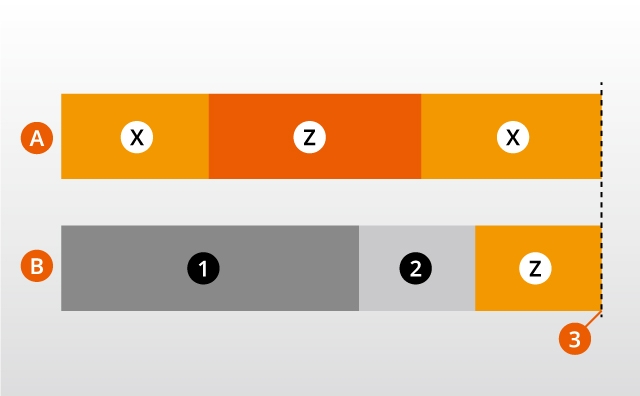

With Override synchronized operation (50%)

A: Turret A

B: Turret B

1: Dwell (standby time)

2: Supporting Functions

3: No program misalignment

Without Override synchronized operation (50%)

A: Turret A

B: Turret B

1: Dwell (standby time) No change in time

2: Supporting Functions

3: Program misalignment occurred

Manual pulse handle operation

The machining program can be operated at any speed by turning the handwheel of the CNC system by hand. The approach position and points where interference is likely to occur can be carefully checked.

HQR-200/3 NEO

HQR-250/3 NEO

| Spindle bore | Φ3.58" |

| Chuck size | 10″ |

| Max. machining diameter | Φ12.6" |

| Max. machining length | 33.86" |