Additive Manufacturing (AM)

Additive Manufacturing (AM) technology is a layer-by-layer processing technique that uses lasers or wire arcs to stack metal and create various 3D shapes. It enables the manufacturing of materials close to the final shape (near net shape), cladding with dissimilar metals, and repair of worn or chipped parts.

Hybrid multi-tasking machines equipped with Additive Manufacturing technology

By integrating additive manufacturing technology into multi-tasking machines and simultaneous 5-axis machining centers, it becomes possible to perform metal layering and finish machining all in one machine, greatly expanding the scope of metal processing. Depending on the application, you can choose from two types of hybrid multi-tasking machines using laser metal deposition and wire-arc AM.

| Additive Manufacturing Type | Size | Repair (modification)  | Coating (as sealing purpose)  | Microfabrication Coating (fine modeling)  | Near Net shape (partial modeling)  |

|---|---|---|---|---|---|

| Laser Metal Deposition [Heat generation] Laser [Material] Metal powder | Medium to rough surface | 〇 | 〇 | 〇 | ◎ |

| Wire-arc AM [Heat generation] Arc [Material] Metal wire | Rough surface | 〇* | ◎ | △ | ◎* |

*Depends on application

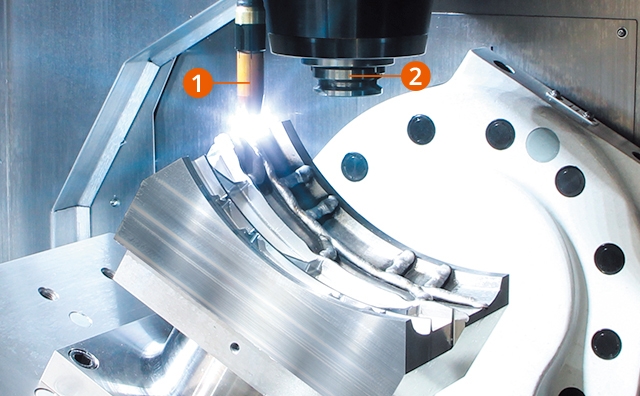

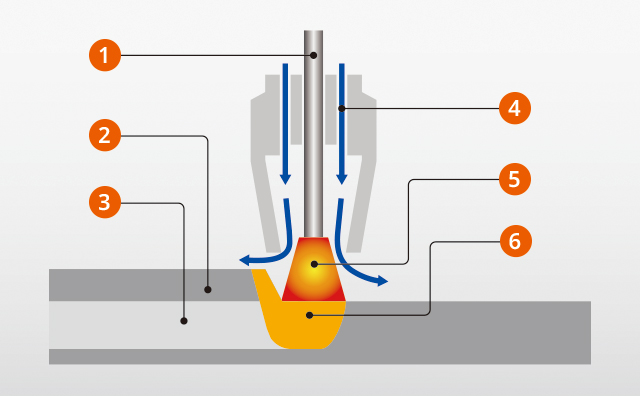

Laser Metal Deposition

High-speed additive manufacturing and powerful joint of dissimilar metals

High-speed additive manufacturing by high power laser

Powerful joint of dissimilar metals

High strength

All processes, from machining to 3D additive manufacturing, are incorporated in just one machine to reduce production lead time

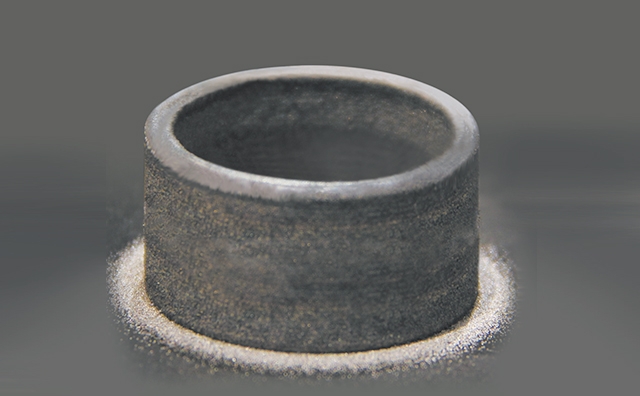

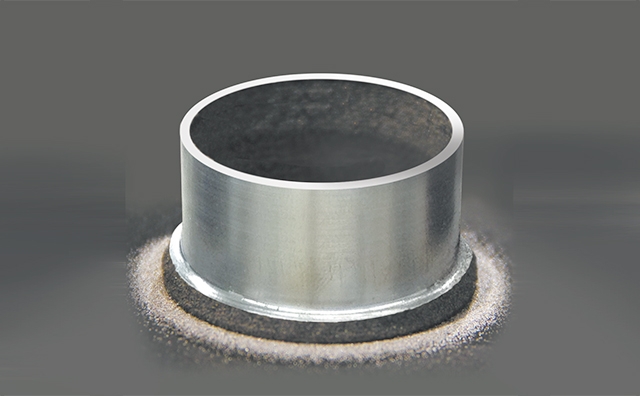

Process of additive manufacturing and machining

- Additive manufacturing

- After additive manufacturing

- After finish machining

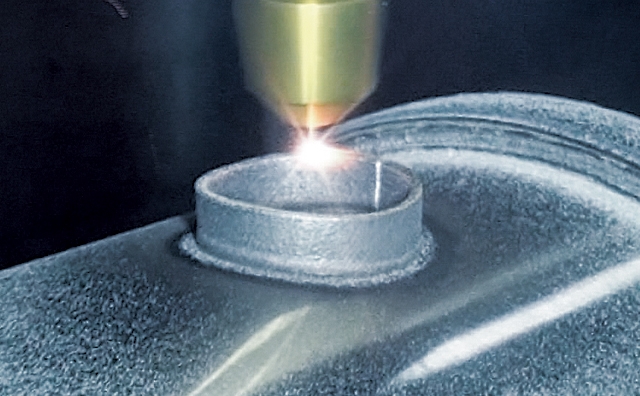

Wire-arc AM

Wire Arc for high speed additive manufacturing

- Automatic welding by program

The materials used in the process, such as aluminum and iron, are easy to obtain and handle.

Highly reliable arc welding

High speed additive manufacturing

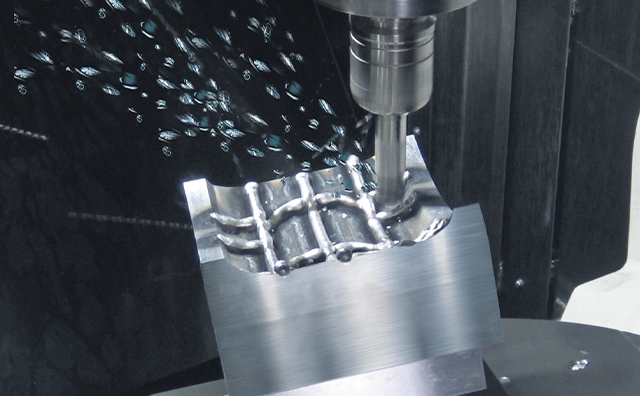

Additive manufacturing and simultaneous 5-axis machining

- Wire-arc AM

- Simultaneous 5-axis machining

AM head