Shop Builds Success on Advanced Machining Capability

Whirlwind Propellers in El Cajon, California, wanted to grow and expand its product offerings, but farming out the machining of its propeller hub assembly components had severely hindered the shop’s progress. Not only was the shop unable to fully control its processes and production lead times, but outsourcing work led to poor cost-effectiveness, which, in turn, stifled new product design.

According to Jim Rust, president of Whirlwind Propellers, the shop’s product line stagnated. They weren’t developing new designs nor making design improvements to existing products. That was, he pointed out, until they incorporated Multi-Tasking machine technology into the shop’s part-production operations.

Whirlwind Propellers produces two types of propellers: constant-speed propellers for aerobatic aircraft and ground-adjustable propellers for simple light aircraft. One propeller hub assembly can involve up to 23 different parts. The low volume/high mix production strategy required to keep up with customer demand for propeller hubs eventually made outsourcing virtually impossible for the shop.

“Hub assemblies are entirely comprised of close-tolerance, high-precision parts,” explained Rust. “Most are aluminum, but there are some made from 440C stainless steel. And most are round in shape, but they require lots of milling from solid billets. For example, hub housings are one of the largest assembly components. They begin as a 10" round piece of stock weighing about 85 lbs and when completely machined are only 7 lbs.”

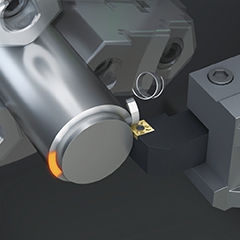

URA produces the molds with 3D machining techniques on a recently acquired Mazak VARIAXIS i-700T Vertical Machining Center. The machine combines multiple surface, 5-axis milling with advanced turning capability to process complex parts in a single setup. An advanced rotary/tilt table provides high positioning accuracy, and the machine features a Capto C6, 40 hp, 18,000 rpm spindle along with a 150˚ tilting A axis and a 360˚ rotating C axis with a direct-drive motor capable of 1,100 rpm for turning. The machine handles parts up to 33.46" in diameter and 19.69" high with X, Y and Z-axis travels measuring 24.8", 43.3" and 23.6", respectively. URA added productivity enhancing options that include high-pressure coolant, expanded tool magazine, chip conveyor and in-machine probing.

A.W. Miller representative Sebastien Bapst explained that what makes the VARIAXIS i-700T unique is its turning capability. Before the shop acquired the machine, some molds had to be turned on its big manual lathe, then milled in up to seven setups on 3-axis machines.

“We needed the turning for our round parts and moldmaking,” Vachon said, “Everything was a new setup on a 3-axis machine. With the VARIAXIS, the table just flips and keeps working.”

When equipped with a small-diameter ball end mill, the machine’s 18,000 rpm spindle produces high-quality mold finishes. While URA still outsources some post-machining polishing, Vachon said they save money because their polishing needs are less. They save time because the surface finish is much better after the machining process, “It takes the supplier who does our polishing half the time it did prior,” he added.

In addition to the VTC-200B and the VARIAXIS i-700T machining centers, URA has seven Mazak machines with a diverse set of capabilities, including an INTEGREX 300-IV S Multi-Tasking Machining Center with a machining length of 60" and integrated turning capabilities with second spindle as well as full 5-axis milling capabilities for complete DONE IN ONE® part processing. Also on the shop’s floor are a QUICK TURN 250 Turning Center, VCN-410A and VCN-410B Vertical Machining Centers, and a VTC-300C Vertical Traveling Column Machining Center. The shop does not purchase a machine to fulfill a specific contract, but will instead acquire equipment first, then secure work for it.

“URA has a diverse set of machines and capabilities,” said A.W. Miller General Manager Jean Seguin. “Considering the variety of the work the shop does, and that they want to turn it around quickly, we looked at equipment that would provide more capabilities and require less setup time. They are active in all kinds of different industries, which requires a lot of flexibility.”

Additionally, the ease of use of the MAZATROL programming system on its Mazak machines was an important consideration during the initial purchase of each of the machines. “At the time of our first machine, programming was not our strong suit,” said Yanick Auger, co-owner of Usinage R.A. Inc. “There was practically no learning curve, and our machinists can seamlessly move from running one Mazak to the next. Now our machinists are comfortable working with MAZATROL. The software has definitely evolved, but it’s still just as user friendly, if not more.”

Some of URA’s compression molds are used to form large, highly contoured snowmobile skis from ultra-high-molecular weight (UHMW) polyethylene, a tough, abrasion-resistant polymer. One of the shop’s long-time customers produces a selection of UHMW parts such as skis and track kits for ATVs, as well as some rubber parts like tracks for tank treads.

In its moldmaking operations URA works primarily with steels, although it also machines aluminum, bronze, cast iron and a variety of plastics. Tolerances generally are in the range of ±0.0005". In fact, “Half a thousandth is easy for us to maintain, with consistent repeatability,” Vachon said.

Founded in 1989 by René Auger, URA is now owned by his son Yanick together with Vachon. URA has 13 employees total, including management, and works two shifts a day. Capabilities include CNC and conventional milling, MIG and TIG welding and gear making. “We specialize in big parts but don’t want to have a big shop with 50 or 60 employees,” said Auger.

URA managers work closely with employees to involve them in operational decisions. The majority of those working at URA are loyal, long-time employees. As Auger puts it, “Our team greatly contributes to improving plant productivity. They are as critical to our success as is the high capability and versatility we get from our Mazak machines.”