Reliable Machines and a Woman’s Leadership Continue Shop’s Success

In 2008 when Courtney Silver decided to help her husband Robert “Bobby” Ketchie manage his manufacturing business with her background in finance and supply chain management, she never thought for a moment that she’d end up running the Concord, North Carolina-based machine shop. Together, the couple operated and grew Ketchie Inc. until Bobby passed away in March of 2014. And to ensure the continuation of her husband’s legacy, Ketchie-Silver became the president and sole shareholder; just a year later, the shop had already received national recognition as a Certified Woman Owned and Operated Business Enterprise and today continues to grow with capital investments in new equipment and technology.

When it comes to technology, the shop’s philosophy, in the words of Silver, “is to acquire the very best built machines and run the heck out of them.” And for several of the shop’s machines, that philosophy means some of the company’s machine tools have seen over thirty years of use.

The shop’s strategies are working. Over the past four years, Ketchie has experienced double-digit revenue growth year over year and has expanded its workforce over 20%. It has also invested over $2.5 million in machine technology for work it already has and to win new additional work.

“Over the past 12 years I’ve been here at Ketchie, my passion for manufacturing has grown exponentially,” said Silver. “We are a full-service precision machine shop able to provide scalable, comprehensive supply solutions for both government and commercial customers. Our goal is to always be the most respected custom manufacturer for having the highest quality people, products and service.”

Ketchie’s very first CNC was a Mazak M4 Turning Center purchased by Bobby Ketchie’s father Ed Jr. in the late 1970s. Since then, all the shop’s machines have been made by Mazak. Silver once asked Ed Jr. why he acquired only Mazak machines, and his reply was simple: for Ed Jr., the key factor in his decision was “the reliability and the Mazak MAZATROL control technology that allows for both EIA/ISO and conversational programming,” according to Silver.

In addition to highly reliable machines, the shop has incorporated manufacturing technology that includes Multi-Tasking part processing and automation. But equally as important, according to Silver, is the fact that the shop has stuck with the same brand of machine tools, which in itself provides several benefits. Among them is the ability to quickly get new machinists up to speed, not only running machines, but also setting them up and programming them.

“He realized right away that the conversational programming language would make training new employees easier and faster, and it still does for us,” she added Ketchie now has eight turning centers and four horizontal machining centers, including Mazak HCN-6000 and HCN-6800 Horizontal Machining Centers, QUICK TURN 350MY and 450MY Turning Centers with Multi-Tasking capability and a PALLETECH automation system. One of the most recent HCNs replaced a Mazak machine that the shop ran for 30 years, and they are still running a Mazak turning center that was purchased in 1987.

“There is no better reason to stick with the same brand of machine tools than having machines that have lasted for three decades,” said Silver. “That’s strong proof of Mazak’s Rock Solid reliability.”

The Mazak HCN-6000 and HCN-6800 are heavy-duty machines that deliver the power and versatility that Ketchie needs for productive and precise large-part machining, as well as a special integral spindle/motor headstocks that minimizes vibration and heat generation for the highest level of part quality. While both machine models come standard with 2-pallet changers, one of Ketchie’s HCN-6000s is part of the shop’s PALLETECH System, which features a modular design that makes it easy for the shop to add pallets, loading stations and part wash stations at any time as its production needs change.

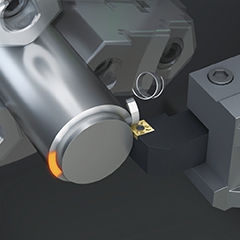

As MY configuration machines, the QUICK TURN 350MY and 450MY feature milling capabilities and Y-axis off-centerline functionality along with standard through-hole chuck packages to process a wide range of part sizes in a single setups. Sporting 12-position direct-drive turrets that eliminate the use of belts for improved part surface finishes and reduced maintenance, the machines can accept both VDI and bolt-on tooling and come standard with 10 hp (7.5 kW), 4,000 rpm live spindles.

Machinists at Ketchie do nearly all their part programming at the machines because, according to Ketchie Inc. Plant Manager Terry Smith, “The Mazak controls are so user friendly and our parts aren’t extremely complex.” The shop will program some parts with a CAM system, but 99% of the time, jobs get programmed at the machines.

Smith said that Mazak’s MAZATROL programming also significantly shortens learning curves for new, inexperienced machinists and allows them to easily transition from one type of Mazak machine to the next. “We want all our operators to be self-sufficient, which is why they all know how to set up and program their machines,” he explained. “And that’s the real plus about having all Mazak machines with MAZATROL controls. Operators can run our 1987 turning center, then switch to the newest Mazak Multi-Tasking machine without a hiccup.”

One Ketchie machinist that benefited from MAZATROL programming was Jordan Nicholson, a turning center operator who started as an on-the-job trainee with absolutely no machining experience. He quickly progressed from simply manning a machine to setting up and programming, and he said that MAZATROL programming played a key role in quickly getting him to his present skill level, which is successfully running the shop’s QUICK TURN 450MY with live tooling and Y-axis off centerline capability.

“Programming for both milling and turning operations on the same machine was a bit daunting at first,” said Nicholson, “but MAZATROL made the learning curve very short for me because it’s simple and straightforward. So transitioning from an older turning center to running the new one wasn’t as complicated as expected, mainly because of both machines having the same type of control. Once I had the basics down, transitioning over to Multi-Tasking was practically seamless.”

According to Smith, Ketchie bases its technology acquisitions on production flexibility and, most importantly, on the reduction of both setups and machining cycle times. “The Mazak Multi-Tasking Machines with live tooling have really helped reduce both,” he said. “For a lot of our jobs that used to require two or three setups, we now do in one setup with either the QTN-350MY or the 450MY.” He also noted that when the shop can eliminate the need to handle parts – as is the case with single-process, multiple-setup machines – overall quality immediately improves and the risk of stacked tolerances drops.

While Ketchie’s Multi-Tasking Machines provide single-setup part processing, the shop’s six-pallet Mazak PALLETECH system allows it to, according to Smith, “hide a lot of changeover and inspection time because the machine in the system basically runs at 100%.” This gives the shop time to inspect parts or change them over without the machine spindle having to stop.

Most of Ketchie’s work involves components for industrial equipment and heavy machinery made from castings, forgings and raw bar stock. Materials include cast iron, stainless steel and tool steels, and machining cycle times are anywhere between two minutes to one and a half hours with required tolerances as tight as 0.0003" to 0.0005", depending on part and machine.

“Due in large part to our advanced Mazak machining technology, last year, we were able to present a customer with an annual savings of $30,000,” said Silver. “We proactively reevaluated setups and cycle times and other aspects of their particular job, and we were able to reduce both – and pass that savings on to the customer, allowing them, in turn, to be more competitive. And as we continue to equip our extremely talented team with the latest in manufacturing technology, we foresee many more opportunities to save our customers time and money with our Mazak technology.”