Environmental Activities

Mazak's approach to decarbonization

By 2030, we will achieve a 50% reduction of our carbon footprint*.

- * Compared to 2010 levels

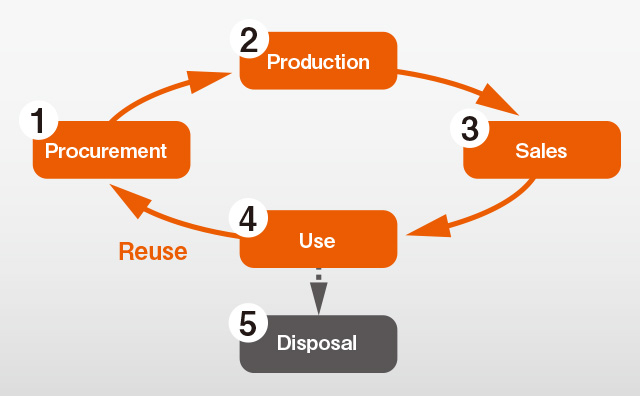

Mazak has positioned the environment as one of its important management issues in order to achieve a carbon-free society and is promoting "Mazak Go GREEN” activity. This activity is aimed at reducing CO₂ emissions throughout the product life cycle, from product development, customer use and disposal process. We aim to develop energy-saving technology by analyzing data collected from our products installed in our Mazak iSMART Factory™. Using this expertise, Mazak will continue to develop energy efficient products to contribute to decarbonization in the customer's factory.

Carbon footprint: The visual output of the amount of carbon dioxide (CO₂) emissions produced through the whole product life cycle.

Visualization of CO₂ emissions throughout the product life cycle

- 1:|Procurement

- 2: |Production

- 3: |Sales

- 4: |Use

- 5: |Disposal

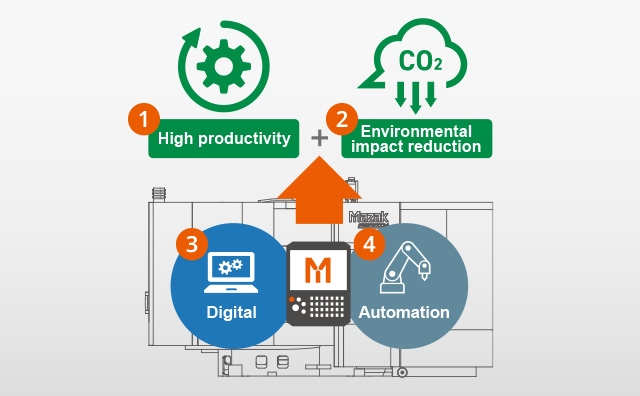

MAZATROL achieves both high productivity and reduced environmental impact

Mazak machine tools, with MAZATROL CNC systems at the core, enable process integration when equipped with energy-saving equipment, optimized control of coolant equipment, the use of AI and digital technology, and automation systems. Mazak machine tools achieve both even higher productivity and reduced environmental impact.

- 1:|High productivity

- 2: |Environmental impact reduction

- 3: |Digital

- 4: |Automation

Environmental performance of the NEO series

During the product life cycle of a machine tool, CO₂ emissions are largest during the period when the machine is in use at the customer's factory.

The Mazak NEO series enables customers to reduce CO₂ emissions at their plants by significantly reducing power consumption compared to conventional machines, while maintaining high productivity and high-accuracy machining performance. Compared to conventional models, the power consumption has been reduced by 46%.

Approaches to Reducing CO₂ Emissions

We are committed to developing technology for decarbonization through productivity improvements. To achieve both of these goals, not only do we install energy-saving technology in machine tools, but we promote approaches such as utilization of AI and digital technology, process integration, and resource saving / waste reduction. Through these approaches, we believe that we can reduce our environmental impact without compromising our customers' productivity, and contribute to the development of a sustainable society.