Omni Mold Ltd.

Aiming to be Number One

Singapore, a popular tourist destination and an international city, is also one of the largest industrial countries in Southeast Asia. Omni Mold is located in the western area of the country, where manufacturing industries thrive. The company is dedicated to becoming the number one by adopting the latest technologies and focusing on business improvement.

Singapore-based mold manufacturer

“Our mission is to provide a one-stop turnkey solution at competitive prices for all plastics engineering needs.” Mr. Simon Tan, Chief Technology Officer (CTO) and Executive Vice President of Sunningdale Tech Ltd. said. Established in 1989, Omni Mold, a subsidiary of Sunningdale Tech Ltd, has emerged as a leading authority in ultra-precision mold manufacturing within Singapore. Renowned for its expertise in designing, engineering, and producing intricate and highly detailed steel molds, the company serves industries with stringent specifications, including electronics, automotive, consumer IT, telecommunications, pharmaceuticals, and medical devices. With a rapidly expanding clientele fueled by the surging demand for high cavitation, high precision plastics injection molds, Omni Mold has widened their customer base now extending across America, Europe, MENA, and the Asia Pacific regions.

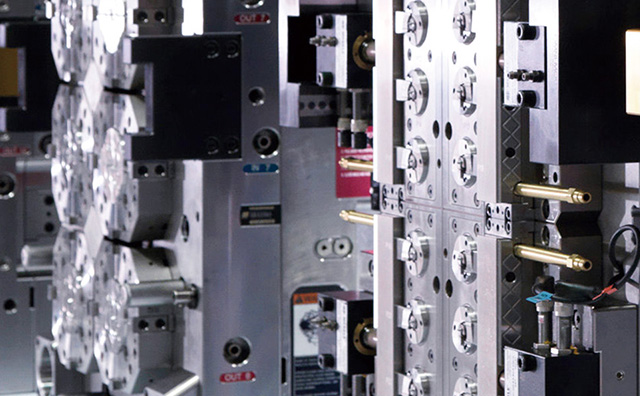

The company makes a plastic injection mold that specializes in ultra-precision, high-complexity, and high-cavitation. With a workforce exceeding 180 highly skilled individuals, the company benefits from a robust team dedicated to excellence. Moreover, their state-of-the-art facility boasts advanced computer software and cutting-edge machine tools, providing the necessary infrastructure for precision manufacturing and innovation. Thus, enabling them to achieve the highest standards of accuracy and efficiency in mold manufacturing. From concept to completion, they employ a meticulous approach to ensure that each mold meets the exact specifications and requirements of their clients.

Two strengths fortifying the operations

In response to the escalating demand for high cavitation molds for medical parts and liquid silicone molds, Omni Mold decided to make strategic investments in advanced CNC machines. Among these investments were the Mazak INTEGREX i-100 and INTEGREX i-200S models, chosen to pilot into higher precision medical tooling. Since its introduction in 2006, the INTEGREX i-200S has played a pivotal role in machining molds for blood tubes, showcasing its exceptional capabilities and contributing significantly to their growing reputation as a world-class medical tooling company.

Ultra-high precision tooling for complex parts and highvolume productions, as well as high-demanding tooling for high-performance engineering plastics – these are the top two products of Omni Mold. To enhance their manufacturing capabilities and efficiency, they integrated Mazak machines into these operations. The state-of-the art machines not only improved the production time but together with the expertise and assistance of Mazak’s highly trained and professional engineers, they help to optimize the processes and maximize the output. Mr. Tan emphasizes the significant advantages of being in close proximity to Mazak Singapore, highlighting the benefits derived from the presence of well-trained engineers who offer professional support to their operations. This collaboration has further solidified Omni Mold’s position as a leader in the mold manufacturing industry, ensuring the continuation of delivering superior quality and precision to the customers.

Vision and Strategy for the future

Mr. Tan elaborated on the vision of Omni Mold, emphasizing the company’s aspiration to become the preeminent and most adept mold manufacturer within the world. “Omni Mold’s vision is to be the best and most well managed mold manufacturer.” He stressed the paramount importance of continually challenging and refining operational methodologies to ensure unparalleled customer satisfaction. “Our focus is on continually challenging and improving the way we do things to ensure total customer satisfaction. We recognize that it is the quality of our people that will help us achieve this vision. As such, we are committed to a series of initiatives aimed at unleashing the full potential of our employees through a steadfast emphasis on quality, comprehensive training programs, and empowerment initiatives.” The company formulates a strategic approach - to continually look for opportunities, investments and manufacturing sites that align with the standards outlined in its mission and vision. Through this deliberate approach, they endeavor to harness newfound expertise and infuse added value into their operations, all in the pursuit of fulfilling their overarching vision for excellence. “We will continue to keep abreast with technological advancement and innovations.” Mr. Tan eagerly anticipates the future with a forward-looking perspective.

Omni Mold Ltd.

| CTO & Executive Vice President | Simon Tan |

| Head Office | 51 Joo Koon Circle, Singapore 629069 |

| Number of employees | 180 (Omni Mold Ltd.) |