2D AUTOMATION

QUICK CELL

Compact single machine automation with an economical investment

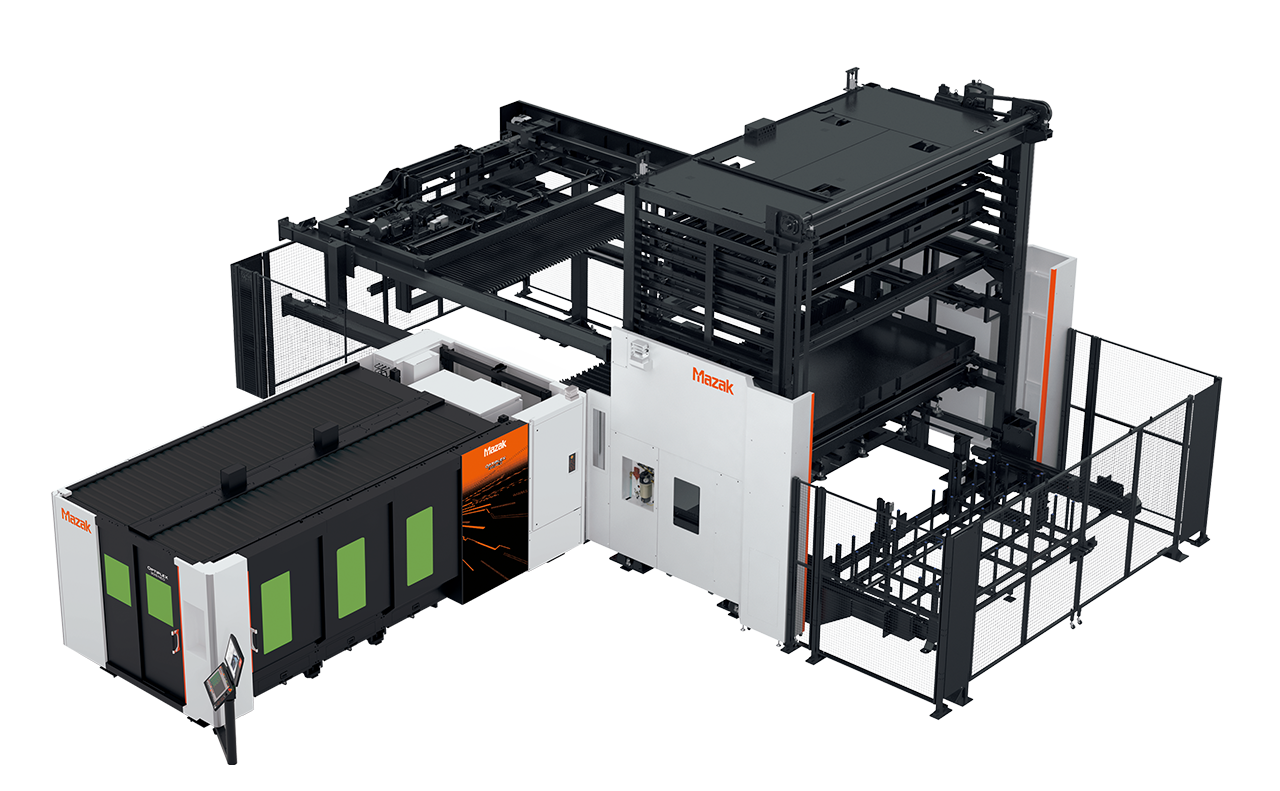

The QUICK CELL 3015 Compact Automation Cell utilizes rugged construction and an innovative design to deliver high performance for fabrication job shops and production environments. The base design is a very compact load/ lnload, which can be configured as a full FMS with 6, 10 or 14 shelves. The number of shelves for material compared to finished parts can be specified at the time of order. QUICK CELL utilizes independent load and unload drive systems, reducing work piece material changeover times. A scheduling unit is integrated into the QUICK CELL to simplify planning and operation. Quick Cell is available in the following configurations.

Configuration examples

QUICK CELL 3015 with Pallet Changer Extension

QUICK CELL 3015 with 6 Level Stocker

QUICK CELL 3015 with 10 Level Stocker

QUICK CELL 3015 with 14 Level Stocker

Video library

Specifications

| Format | QUICK CELL 3015 with Pallet Changer Extension | QUICK CELL 3015 with 6 Level Stocker | QUICK CELL 3015 with 10 Level Stocker | QUICK CELL 3015 with 14 Level Stocker |

|---|---|---|---|---|

| Number of machines serviced | 1 | 1 | 1 | 1 |

| Maximum sheet size | 120" × 60" | 120" × 60" | 120" × 60" | 120" × 60" |

| Maximum sheet thickness | 1" | 1" | 1" | 1" |

| Maximum pallet capacity | 6614 lbs | 6614 lbs | 6614 lbs | 6614 lbs |

| Number of shelves | na | 6 | 10 | 14 |

| Material stack height | 3.54" | 3.54" | 3.54" | 3.54" |

| Loading type | Suction cups | Suction cups | Suction cups | Suction cups |

| Unloading type | Rake | Rake | Rake | Rake |

| Load/unload cycle time | 60 seconds | 60 seconds | 60 seconds | 60 seconds |

| Connection to AS/R | na | na | na | na |