2D AUTOMATION

M-SERIES

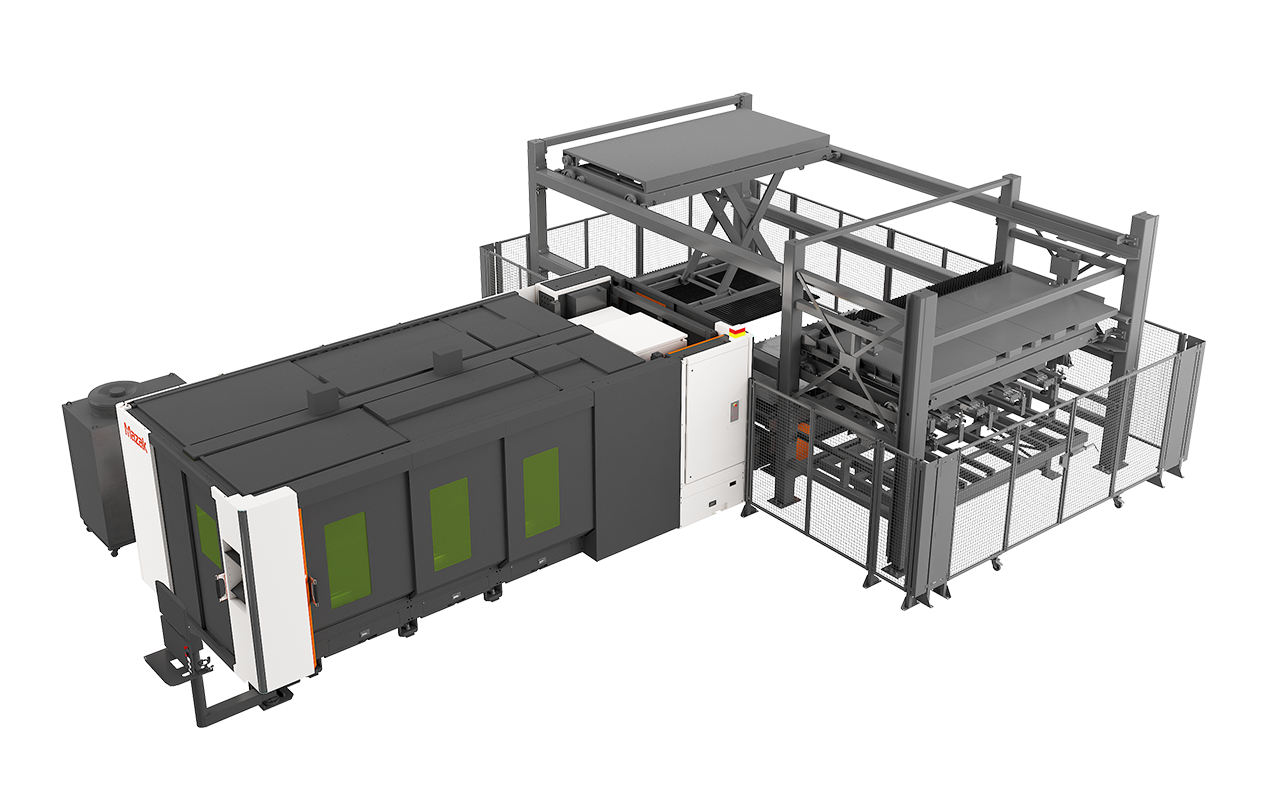

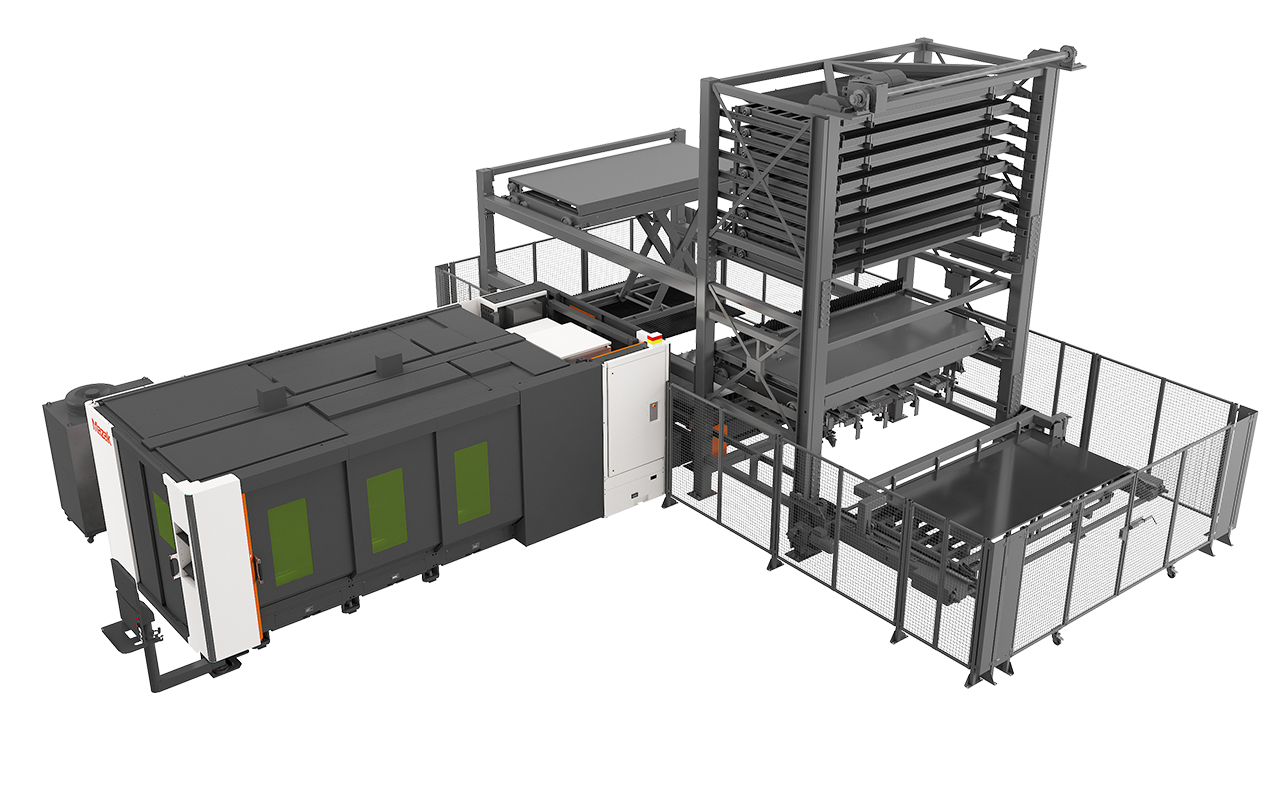

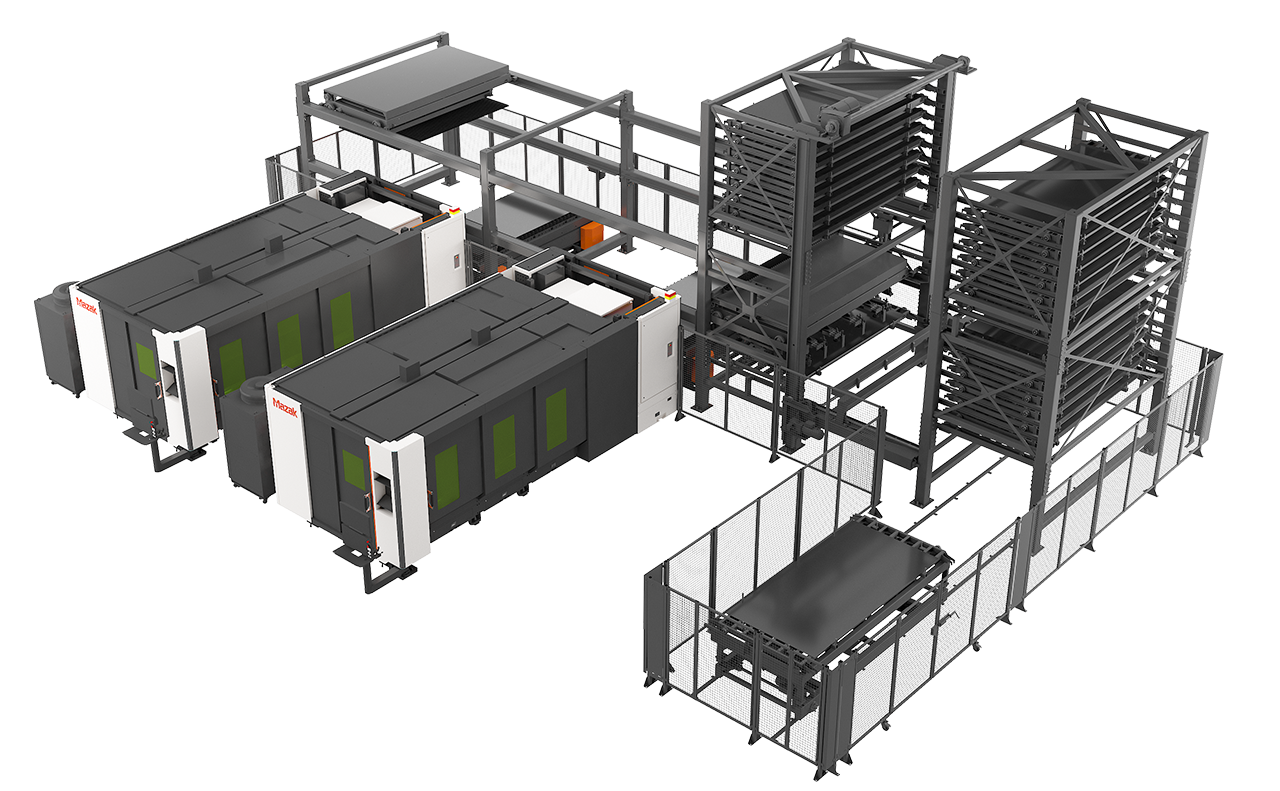

Maximum flexibility for job shops and short run production

Mazak’s M-Series of automation is the most flexible solution for meeting difficult customer needs. A wide range of peripheral devices and functions expand the range of applications including conveyors, over/under carts and labellers. Systems feature a small footprint and highly customizable configurations.

M-Series systems are available in a variety of 3015, 4020 and reverse flow configurations. They can be integrated into an AUTOMATED STORAGE/RETRIEVAL System for even greater capacity.

Mazak’s M-Series automation can also be designed to incorporate systems to separate parts and automatically load them onto pallets in production environments.

Configuration examples

Video library

Automation specifications

| Format | 3015 | 4220 |

|---|---|---|

| Number of machines serviced | Up to 3 | Up to 3 |

| Maximum sheet size | 120" × 60" | 160" × 80" |

| Maximum sheet thickness | 1" | 1" |

| Maximum pallet capacity | 6614 lbs | 11023 lbs |

| Number of shelves | Customizable to ceiling height | Customizable to ceiling height |

| Material stack height | 1.89” raw / 3.54” UL (customizable) | 1.89” raw / 2.36” UL (customizable) |

| Loading type | Suction cups | Suction cups |

| Unloading type | Rake | Rake |

| Load/unload cycle time Under | 60 seconds (based on one-laser configuration) | 80 seconds (based on one-laser configuration) |

| Connections to AS/R | Yes | Yes |