2D AUTOMATION

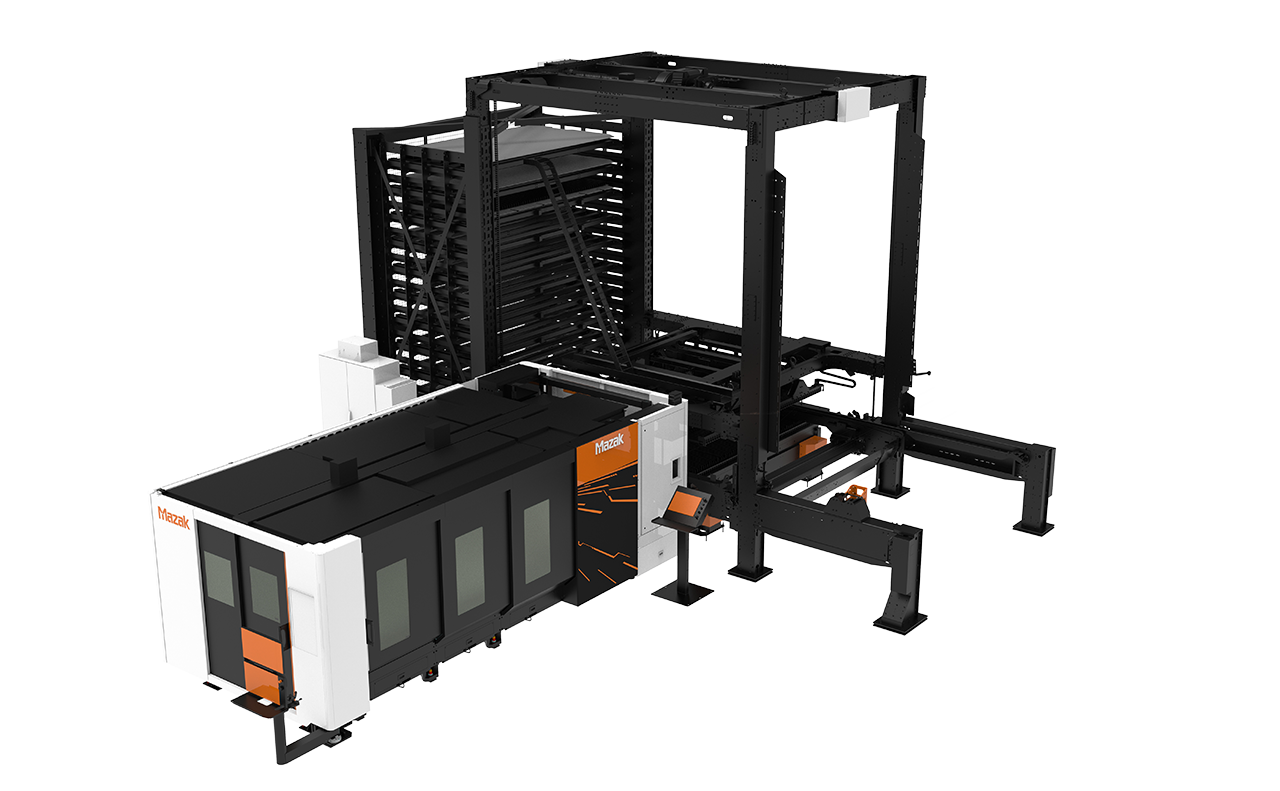

Ez COMPACT

Maximizing the available floor space for job shops

Mazak’s Ez Compact automation is designed to maximize the available space for job shops. The expandable design allows customers to grow from one material tower to 2-tower storage system or more with all cut parts returning to the towers. Available in a variety of 3015, 4220, and reverse flow configuration. The series is limited to a one-laser system.

Mazak’s Ez Compact automation can also be designed to incorporate systems to separate parts and automatically load them onto pallets in production environments.

Configuration examples

Video library

Specifications

| Format | 3015 | 4220 |

|---|---|---|

| Number of machines serviced | 1 | 1 |

| Maximum sheet size | 122" × 62" | 164" × 82" |

| Maximum sheet thickness | 1" | 1" |

| Maximum pallet capacity | 6614 lbs | 6614 lbs |

| Number of shelves | Customizable to ceiling height | Customizable to ceiling height |

| Material stack height | From 3.94" to 11.81" (customizable) | From 3.94" to 11.81" (customizable) |

| Loading type | Suction cups | Suction cups |

| Unloading type | Rake | Rake |

| Load/unload cycle time | Around 120 seconds (depends on the machine height) | Around 180 seconds (depends on the machine height) |

| Connections to AS/R | No | No |