Laser Processing Machines

Automation Solutions

Mazak's Flexible Manufacturing System (FMS) provided with laser processing machines, which boasts the world's best track record, has evolved even further. Mazak was the first manufacturer to introduce laser processing machines into an FMS and an automation system. FMS, which boasts an extensive delivery record, is also introduced as the core of our production equipment at our domestic and overseas production plant. With our extensive knowledge and experience in automation gained over many years, we will suggest the most suitable automation system for your needs.

EXTENSIBLE MANUFACTURING CELL

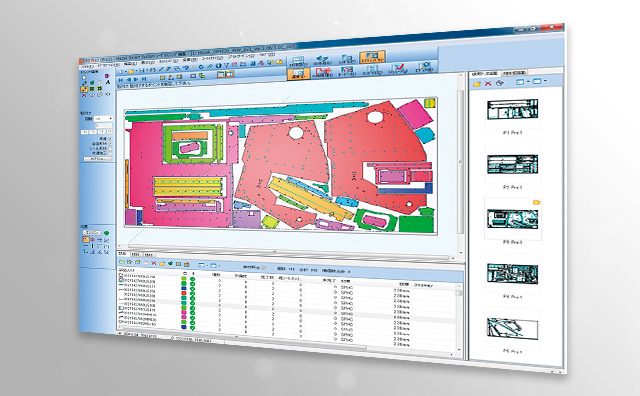

Flexible Laser FMS

Worksheets stored in the material stocker are loaded onto the machine sheet by loader and the cut sheets are unloaded automatically according to the schedule. Since the loader and unloader are on the same line, it is possible to expand the number of machines or shelves according to your requirement.

- Even after installing a standalone system, it is possible to expand to CELL or flexible manufacturing system. It can be extended to a maximum of 4 machines.

- The system features a high degree of flexibility for expansion, such as adding shelves and management controllers, and connecting to stockers.

SMART CELL

An economical investment for high-performance automation

The SMART CELL robotic sorting system utilizes a 6-axis industrial robot and an innovative design to deliver high performance for fabrication job shops and production environments. The base design is very compact and provides modular integration in a wide range of configurations. SMART CELL incorporates multiple customizable magnetic or suction cup gripper options for sorting laser cut parts, loading raw material, and removing remnant material. This system is available to suit different types of applications for unattended production and can be integrated with other compact load and unload automation systems from Mazak.

QUICK CELL 3015

Sheet exchange type laser automation

The loader and unloader are driven separately, reducing the time it takes to load and unload materials. It is a space-saving system where loading and unloading are performed at the same location.

- Even after installing a standalone system, it is possible to expand to CELL or flexible manufacturing system. It can be extended to a maximum of 4 machines.

- The system features a high degree of flexibility for expansion, such as adding shelves and management controllers, and connecting to stockers.

Exceptionally quick loading and unloading time

By driving the loader and unloader separately, the time it takes to load materials and unload cut parts is significantly reduced.

Arrangeable according to your needs

- QUICK CELL can be installed even after the laser processing machine is introduced separately according to the customer's production situation.

- Even after installing the standard QUICK CELL, it is possible to add 6-tier, 10-tier, or 14-tier stockers.

- You can choose the number of shelves for storing material pallets and product pallets according to your needs from the 6-tier, 10-tier, and 14-tier stockers.

Space-saving design

By loading and unloading materials and products in the same place, limited plant space can be utilized effectively.

COMPACT MANUFACTURING CELL 3015

Pallet exchange type laser automation

Worksheets both before and after processing are on pallets and stored in the stocker. The number of micro-joints can be minimized in medium to thick worksheets.