Taking the Lead

Fabricator remains competitive by keeping manufacturing processes up to date with Mazak laser, automation, and high-pressure air solutions

Manufacturing is the mainstay of many businesses operating in the Midwest, and Right Angle Steel is no exception. With several metal fabrication job shops located near the company’s headquarters in Nappanee, IN, remaining competitive is a must. President Josh Cook shares, “We like taking jobs that other centers turn down.”

Right Angle Steel did not always operate with this business philosophy. The company had humble beginnings—starting in 2001 out of a pickup truck in a garage. Back then, Cook’s father was the sole employee of the company which mainly operated as a distributor. The number of employees doubled five years later when Cook began working with his father at the company. By the 2010s, he had purchased Right Angle Steel and transformed the business to focus on manufacturing and metal fabrication. This decision led Cook to Mazak and the company’s first laser-cutting machine.

Choosing Mazak

At the time, Cook’s decision to purchase a laser from Mazak was driven by word of mouth. Several of the company’s customers had operated Mazak machines and appreciated their reliability. After purchasing his first used CO2 laser-cutting machine in 2016, Cook saw firsthand the quality equipment Mazak produced and the company’s commitment to customer satisfaction. Mazak’s service support, in particular, stood out to Cook. “Right Angle has always been known as the company that can turn parts faster than anyone else,” shares Cook. “We don't shy away from the hot jobs. We like the challenge of orders that people need turned around in 24 hours or 48 hours or even less. We needed a company that would have machines that supported that philosophy. We can't afford machines to be down for even a day. So, one of the reasons we chose Mazak was the customer service and the speed that we can get things fixed.”

Two years after the initial laser purchase, Right Angle Steel’s team found it necessary to purchase additional equipment and were running five CO2 laser machines to meet production demand. As the company continued to grow, the need for updated machinery and additional space was imperative.

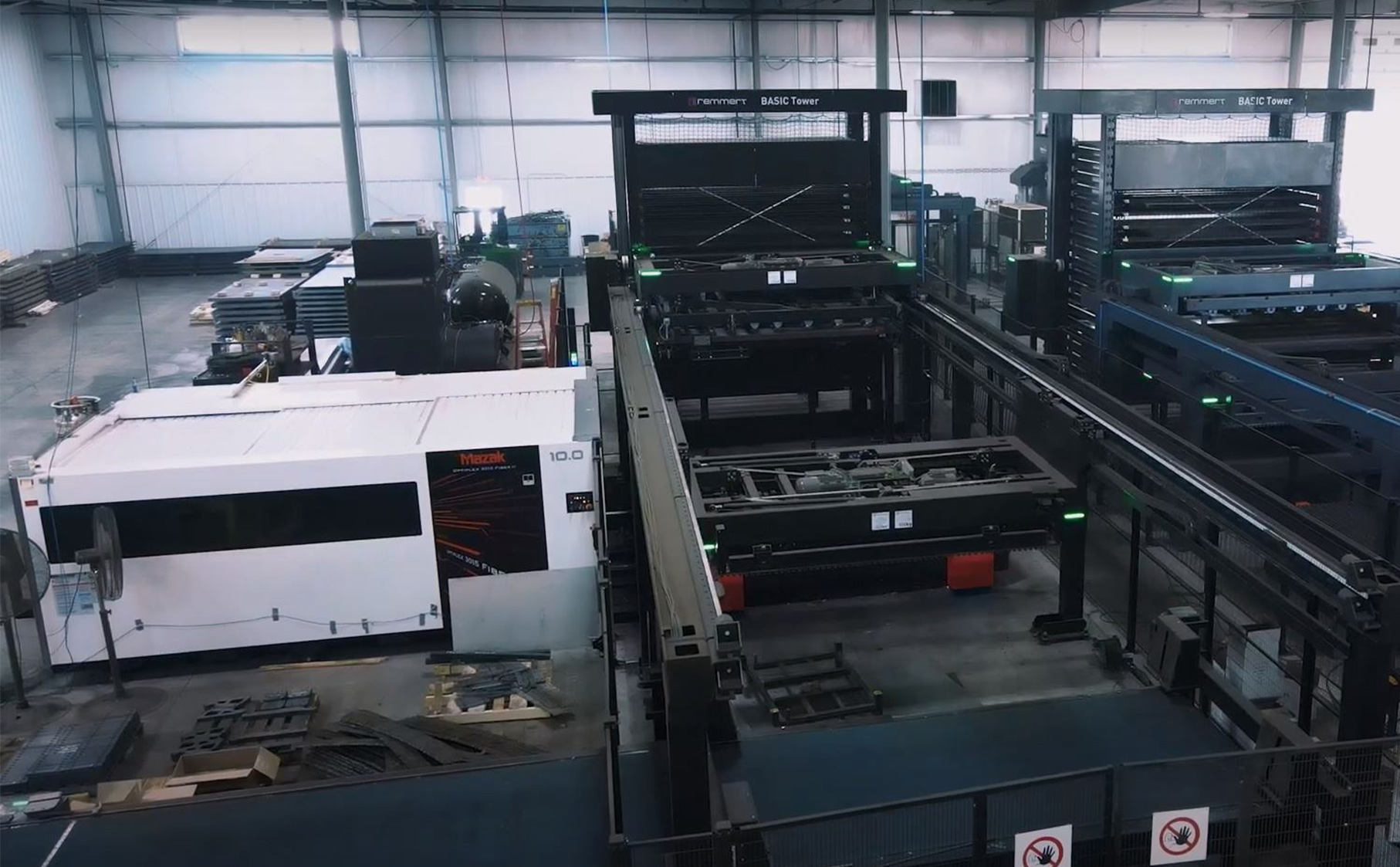

Intent on keeping the company’s manufacturing process up to date, Cook began looking at solutions that would increase production output. He visited Mazak’s North America Laser Technology Center in Elgin, IL to test run his material and cut conditions—a service, Cook found, other laser manufacturers did not provide. The additional opportunity to visit Mazak’s headquarters in Japan sold Cook on fiber laser technology. He purchased the company’s first fiber laser with automation shortly after the trip, Mazak’s OPTIPLEX 3015 FIBER III 10kW and automated storage tower.

Benefits of Updated Technology

The benefits of fiber laser technology and automation were quickly evident to Cook and the Right Angle Steel team. Their ability to rapidly switch between cutting different material like aluminum, stainless, and steel on a fiber laser led to reduced lead times for jobs. The new technology also created capacity to facilitate increased production output and support new customers.

Updated machine features, like modern controls, made it easy for the Right Angle Steel team to quickly get up to speed on how to operate the machines. “With the new controls on the new generations of lasers, it's much easier just to train someone from scratch that's never touched a laser,” says Cook.

Automation additionally increased output by streamlining production. “We wanted to make sure that as parts are coming off the machine that they are instantly ready to ship or to go to the next station, and the automation was a big part of that for us,” explains Cook. Safety played a major role in the decision to purchase automation as it removed the need for employees to load and unload each piece of material, minimizing the risk of injuries on the job.

Adding a high-pressure air system to their manufacturing process created reduced costs for Right Angle Steel and competitive pricing, in turn, for their customers. “Right Angle operates in a very cutthroat space in the fabrication world,” notes Cook. “So, we were looking for the lowest cost per part possible. Some of these new technologies with the 10kW fibers and the air cutting has allowed us to remain competitive.”

Advancing with Mazak

Today, Right Angle Steel operates out of a newly built 100,000 square foot facility serving the RV, trailer, automotive, and heavy equipment industries. Four fully automated flat sheet laser cells and a tube laser—Mazak’s OPTIPLEX NEXUS 3015 FIBER S4, 2–OPTIPLEX 3015 FIBER III 10kW, OPTIPLEX 3015 6kW, and FT-150 FIBER—fabricate everything from small laser-cut parts to large, welded assemblies. Products manufactured by the Right Angle Steel team are shipped to customers nationwide.

With no end in sight to their business growth, Cook intends to continue streamlining the company’s processes by keeping up with the latest technological advancements and partnering with Mazak for laser-cutting solutions. “It was very important for me, when we were looking for machine manufacturers, that I felt valued as a customer, and that I could view the relationship as a partnership,” reveals Cook. “That was where I really felt Mazak exceeded above the other competitors. That was what led us to grow the relationship with Mazak, and we hope to continue to do so in the future.”