First Choice

Looking to reduce lead times, first time laser buyer chooses Mazak as their preferred partner and benefits from reduced costs, quicker turnaround times, and new business

Dusty roads and grape vines greet visitors as they make their way through Lodi, California. Located forty miles south of Sacramento, Lodi is known for its abundant vineyards and grape production. Naturally, community residents and local businesses contribute to the substantial agricultural industry that supports the growing city.

Family owned and operated, Acampo Machine Works is one of those companies—manufacturing vineyard and orchard equipment for the local farm community. President, Craig Edwards started the company 31 years ago primarily as a machinery and equipment repair shop for the food manufacturing industry. Like all successful companies, Acampo evolved over the years and adapted to meet the needs of the local community. Today, Acampo manufactures, sells, and services viticultural and orchard machinery while staying true to its roots by continuing to offer job shop and repair services.

Bringing Laser Cutting In-House

The company’s mower and gondola product lines, job shop, and repair services necessitate a series of bays and shops within Acampo’s 90,000 square feet of space—including spaces designated for mechanical, fabrication, welding, and painting—to organize production. The company additionally outsources processes when necessary. Until recently, laser cutting was one process the company outsourced to a trusted supplier. As lead times for these laser-cut parts increased, the team considered bringing laser cutting in-house.

Purchasing a laser-cutting machine for the first time, the Acampo team made sure to begin by doing their research on the various brand and technology options available to them. From the beginning, Mazak stood out to them as a leader in the industry. Meeting with Mazak’s team solidified the Acampo leadership’s decision to move forward with Mazak. “It was a fantastic encounter. [The salesperson] was very concerned with what we were going to cut and what in the future we were going to cut,” says Edwards. “They were very good about leading us through this journey of owning your first laser.”

Service and Support

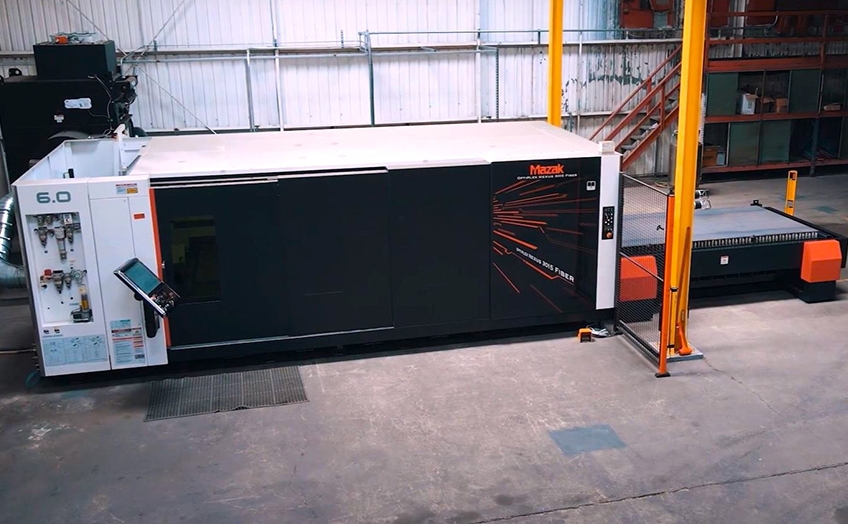

Another factor that played a major role in the team’s purchasing decision was service. Having experienced increased turnaround times due to delayed service on the laser machines they were outsourcing work to, the team agreed service was a top priority when purchasing their own laser. The care and support Mazak provides to its customers was exemplified from the beginning of the partnership. From Mazak’s sales team answering all necessary questions prior to purchasing the OPTIPLEX NEXUS FIBER to Mazak’s service team walking them through the installation process, leaders at Acampo felt that Mazak was with them every step of the way. “We were looking for a partner in this adventure of laser,” explains Edwards. “This is our first time. There are a lot of unknowns. We were looking for somebody that could really walk us through this, and we found that partner in Mazak.”

After-sales support was no different. When the Acampo team came across the challenge of laser-cutting spring steel, they reached out to Mazak and were asked to send a sample of the material they were trying to cut. The Mazak applications team ran the sample and created a program optimized for Acampo’s specific cutting application. “This is what a first-time buyer needs,” shares Edwards. “I need that support. I need to be able to pick up the phone and say how do I do this, and Mazak’s there. They’re absolutely there.”

Value Added

Implementing the new OPTIPLEX NEXUS laser-cutting machine and high-pressure air system from Mazak has resulted in cost savings and quicker turnaround times. “The turnaround time has increased ten times,” explains Edwards. “I can have parts kicked out in five minutes versus five weeks.” The decision to run high-pressure air with their laser has created additional cost savings. “Mazak’s got a great system for running high-pressure air, and they have all the cutting parameters to do most of our cutting on high-pressure air,” says Edwards. “So, I’m not buying nitrogen. I’m saving a lot of money doing this.”

Upgrading their manufacturing process with a laser from Mazak has created an unexpected new business opportunity for the Acampo team. They now take on overflow work from the company they used to outsource their laser cutting to. Once Acampo’s previous supplier for laser-cut parts found out about their new Mazak laser, the company reached out to discuss continuing their business in a different capacity.

As a company that prides itself on perfecting its craft, the Acampo team intends to discover the full potential of their laser-cutting capabilities. As they discover new applications for their laser, they aim to maximize their productivity and intend to purchase another Mazak laser when the need arises. Creating top-of-the-line machinery requires top-of-the-line equipment and support from a trusted partner, and the Acampo team has found that in Mazak.