| Pallet size | Φ600 mm × 500 mm |

| Tool shank (standard) | BT40 |

| Max. spindle speed | 12000 min-1 (rpm) |

| Max. workpiece size | Φ730 mm × 450 mm |

5-Axis Machining Centers

VARIAXIS C

- Large B-axis tilt angle and long X- and Z-axis stroke for multi-surface and 5-axis machining

- Spindle specifications to meet a wide variety of machining requirements

- High-accuracy machining with a highly rigid table supported on both ends and advanced compensation technology

- Automation systems for mass production and multi-variety processing, with a wide range of options

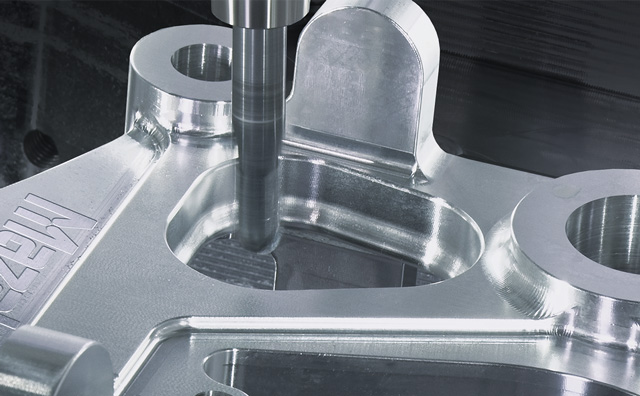

Long stroke for multi-surface and 5-axis machining

A wide stroke range of the X- and Z-axis allows the tool to approach the tip and lower part of the workpiece in multi-surface and 5-axis machining, where the B-axis is tilted significantly. It ensures vibration-free machining with short tool projection.

The high feed rates significantly reduce non-cutting time in simultaneous 5-axis machining, achieving high productivity.

Selectable spindle for machining workpieces

Variety of spindle selections for matching material properties

We offer a lineup of high rigidity and high speed spindle that can perform heavy duty machining of steel as well as high speed machining of non-ferrous materials such as aluminum.. You can select the optimal spindle to suit your workpiece.

| Standard | High-torque* | High-speed* | ||

|---|---|---|---|---|

| Spindle speed | 12000 min-1 | 15000 min-1 | 18000 min-1 | 20000 min-1 |

| Output (40% ED) | 11 kW (15 HP) | 46 kW (62 HP) | 30 kW (40 HP) | 42 kW (56 HP) |

| Torque (40% ED) | 70 N・m | 200 N・m | 105 N・m | 161 N・m |

| Tool shank | BT-40 / BIG-PLUS No.40* / HSK-A63* | |||

- * Option

Machining example (test results)

15000 min -1 high-torque spindle

Φ80 mm face mill (6 teeth)

Speed: 995 min -1

Feedrate: 1552 mm/min

Depth of cut: 5.8 mm

Material: S45C

Material removal rate: 581 cm³/min

High rigidity table

The tilting rotary table is supported at two ends. High-speed, high-precision, and high-rigidity machining is achieved by utilizing roller gear cams in the B-axis and C-axis to eliminate backlash.

| Model | VARIAXIS C-600 | VARIAXIS C-700 |

|---|---|---|

| Max. workpiece diameter | Φ730 mm | Φ850 mm |

| Max. workpiece height | 450 mm | 500 mm |

| Max. workpiece weight | 500 kg | 700 kg |

| C-chamfer | C110 mm | C90 mm |

VARIAXIS C-600 1: H450 mm 2: Φ730 mm

VARIAXIS C-700 1: H500 mm 2: Φ850 mm

High rigidity structure and MAZATROL SmoothAi for high-accuracy machining

High accuracy 5-axis calibration MAZA-CHECK

Position misalignment and incline of the rotary axes can automatically be measured and compensated to realize high accuracy 5-axis machining.

The centers and tilts of rotary axes can be automatically measured and compensated as well as linear axes.

- * Wireless touch probe RMP600 is an optional equipment.

Ai Thermal Shield

Based on spindle speed and temperature of the machine, Ai Thermal Shield suppresses changes in the cutting edge position. It stabilizes continuous machining accuracy through meticulous machine control that takes into account temperature changes, machine position, coolant ON/OFF, and other factors. New algorithms have improved the accuracy of compensation. Furthermore, by accumulating and learning data from subsequent measurements, thermal displacement compensation can be optimized for each machining environment to stabilize machining accuracy.

- Machining

- Workpiece inspection

- Simulation

Smooth Ai spindle*

If chatter vibration occurs during milling, the vibration sensor and AI adaptive control automatically change the machining conditions to suppress the chatter vibration. With the AI, even a less-skilled operator can make adjustments easily in a short time.

* Option

Automated system best suited for multi-product processing

2-pallet changer*

The optional 2-pallet changer allows you to load materials for the next processing step or setup during machining, improving productivity.

| VARIAXIS C-600 | VARIAXIS C-700 | |

|---|---|---|

| Pallet size | □ 500 mm | □ 500 mm |

| Max. workpiece size | Φ730 mm × 450 mm | Φ730 mm × 500 mm |

| Max. loading weight | 500 kg | 600 kg |

* Option

Expandable multi-pallet changer system*

By setting up materials to multiple pallets, the machine can run unmanned for longer periods of time, thus increasing machine availability.

The pallet size, maximum workpiece size, and load are the same as those of the 2-pallet changer specification.

*Optionally available on VARIAXIS C-700

- 2PC

- 4PC, 6PC

MPP (MULTI PALLET POOL)

MPP (MULTI PALLET POOL) is a space-saving multi-stage pallet stocker system developed in response to the growing demand for automation. This automation system is ideal for small-lot, multi-product production and will dramatically improve productivity. The MPP is designed to be attached to the side of the machine, allowing access to the workpiece from two locations: the operator's door and the loading station.

Flexible pallet stocker capacity

6, 12 and 18 pallet storage capacities are available after initial installation.

- 1. 6PC: 3 pallets × 2 levels

- 2. 12PC: 6 pallets × 2 levels

- 3. 18PC: 6 pallets × 3 levels

MAZATROL SmoothAi drives innovation for even higher productivity

Innovative MAZATROL CNC system for higher productivity

MAZATROL SmoothAi provides unsurpassed productivity through even faster and higher precision control while elevating your production with AI and digital twin technology and advanced automation capabilities.

SMC PLUS

The cutting point of the EIA program are compared with the 3D model, and the command points are automatically corrected to reduce cutting residue and generate a smooth path trajectory, resulting in high-quality machining.

Smooth Machining Configuration

Machining features including cycle time, finished surface, and machining shape can be adjusted according to material requirements and machining methods. Since operator can easily adjust and change settings, it is especially effective for complex workpiece contours defined in small program increments.

Digital Twin software for high productivity*

Digital twins recreate real-world factory environments in cyberspace, bringing about innovation in production. By utilizing digital twin software that is compatible with MAZATROL SmoothAi and leverages IoT technology, the machines in the factory can be virtually replicated, leading to significant efficiency improvements in the production process. It provides your office PC with the same environment as the actual MAZATROL SmoothAi. Virtual machine construction enables programming, editing, simulation, and analysis for multiple machines. The setting data of the actual machine is synchronized, which ensures the accuracy of the digital setup.

* Option

Reference Video

VARIAXIS C-600

VARIAXIS C-700

| Pallet size | Φ700 mm × 500 mm |

| Tool shank (standard) | BT40 |

| Max. spindle speed | 12000 min-1 (rpm) |

| Max. workpiece size | Φ850 mm × 500 mm |