| Max. worksheet width | 1525 mm |

| Max. worksheet length | 3050 mm |

| Laser power | 3.0 kW / 4.0 kW / 6.0 kW / 10.0 kW / 15.0 kW / 20.0 kW |

Laser Processing Machines

OPTIPLEX NEO

- Selectable laser oscillator power: 3.0, 4.0, 6.0, 10.0, 15.0, 20.0 kW

- Beam Diameter Control function and Variable Beam Mode function for optimum cutting of various materials and thicknesses

- Design focused on accessibility and ease of operation

- Intelligent functions to automate the setup work

- MAZATROL SmoothLx CNC control

High-speed and high-quality cutting

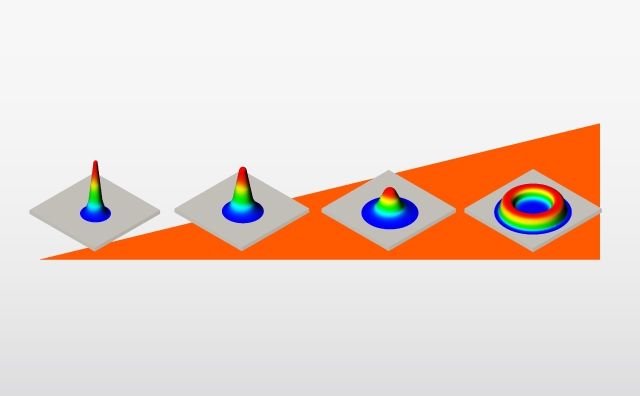

Beam Diameter Control function / Variable Beam Mode function *

Beam shaping technology automatically adjusts the beam diameter according to the material and thickness, and controls where the power density of the laser beam is concentrated. Together, these two functions improve the speed and quality of cutting a wide range of materials.

- * Variable Beam Mode function is only available for laser oscillators with specific power capabilities: 6.0, 10.0, 15.0, 20.0 kW

For thinner material

| Laser power | 3.0 kW | |

Features | Beam Diameter Control function | 〇 |

| Variable Beam Mode function | ー | |

Material: Mild steel / Thickness: 1.0 mm / Assist gas: Nitrogen

For medium to thick material

| Laser power | 4.0 kW | |

Features | Beam Diameter Control function | 〇 |

| Variable Beam Mode function | ー | |

Material: Stainless steel / Thickness: 14 mm / Assist gas: Nitrogen

For thicker material

| Laser power | 6.0 kW / 10.0 kW / 15.0 kW / 20.0 kW | |

Features | Beam Diameter Control function | 〇 |

| Variable Beam Mode function | 〇 | |

Material: Mild steel / Thickness: 32 mm / Assist gas: Oxygen

Wide open doors for easy loading and unloading

Wide opening doors

Sliding doors are installed on the front and side face of the machine, minimizing the floor space required. The doors are designed to provide generous space, with the OPTIPLEX 3015 NEO featuring a front opening of 1200 mm and a side opening of 3210 mm, and the OPTIPLEX 4220 NEO featuring a front opening of 1190 mm and a side opening of 3130 mm. It ensures easier loading and unloading.

Easy adjustment of nozzle center

Integrated Nozzle Camera (option)

A camera can be mounted next to the nozzle holder to check the center position of the nozzle. The nozzle center can be easily adjusted by turning the dial while viewing the operation screen.

Automatic detection of machining area for nesting

Camera Network Nesting (option)*

Camera inside the machine detects the remnant material and automatically identifies the cutting area for nesting.

- * MAZAK SMART SYSTEM is required for Camera Network Nesting.

Wide and flat screen for easier operation

CNC system MAZATROL SmoothLx

Operators can see the entire nesting board at a glance with the 21.5 inch wide screen. Apart from the Emergency Stop and Rotary Switch buttons, operational buttons feature a flat design. Pictograms make the operation more intuitive and user-friendly.

Reference Video

OPTIPLEX 3015 NEO

OPTIPLEX 4220 NEO

| Max. worksheet width | 2050 mm |

| Max. worksheet length | 4120 mm |

| Laser power | 3.0 kW / 4.0 kW / 6.0 kW / 10.0 kW / 15.0 kW / 20.0 kW |