| Tool shank (standard) | BT30 |

| Max. spindle speed | 12000 min-1 (rpm) |

| Table size | 600 mm × 400 mm |

Vertical Machining Centers

FF-400V/30 L

FF-400V/30

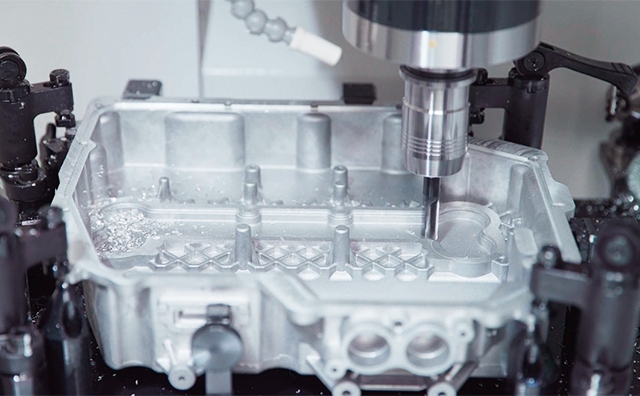

- Compact and highly rigidity machine equipped with a high-speed BT30 spindle for small parts machining

- Table type is selectable to meet your machining requirements

- Z-axis stroke of 400 mm and maximum tool length of 250 mm allows machining large workpieces

- Rapid traverse rate 60 m/min (all axis) and high acceleration (X/Y/Z = 1.1/1.2/1.9G)

Equipped with high speed, high accuracy, compact BT30 spindle for small parts machining

Compact, high performance 12000 min-1 standard spindle. Designed to perform a wide variety of machining efficiently.

Spindle specification for a variety of applications

12000 min-1 standard spindle

20000 min-1 high speed spindle (optional)

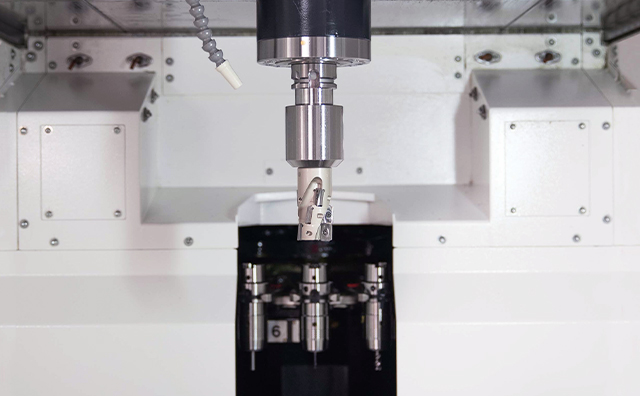

High speed armless tool changer

The standard tool storage capacity is 14, and 26 is available as an option.

High speed positioning

X-, Y- and Z-axis rapid traverse rate 60 m/min

Table Variation

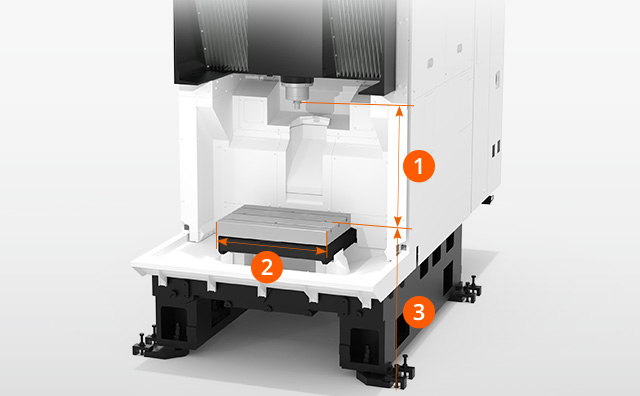

Fixed table (FF-400V/30 L)

Equipped with a 600 mm × 400 mm fixed table. There is enough machining area even with a tall hydraulic fixture on the top face of the table.

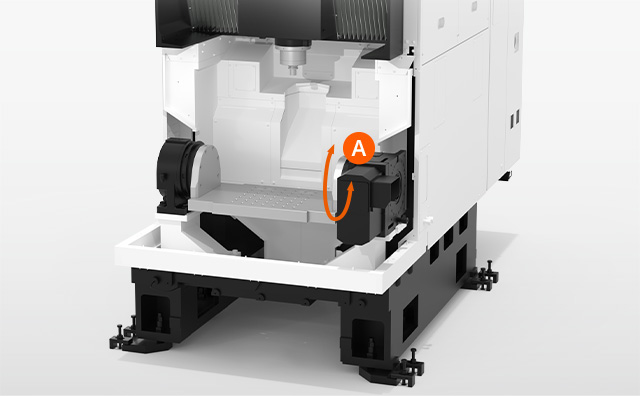

A-axis table (FF-400V/30 L)

The A-axis table allows indexing at any angle. This improves productivity by enabling the machining of top, side and slanted surfaces in a single setup.

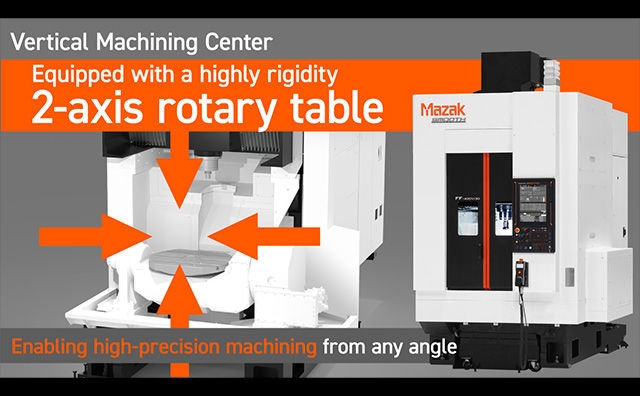

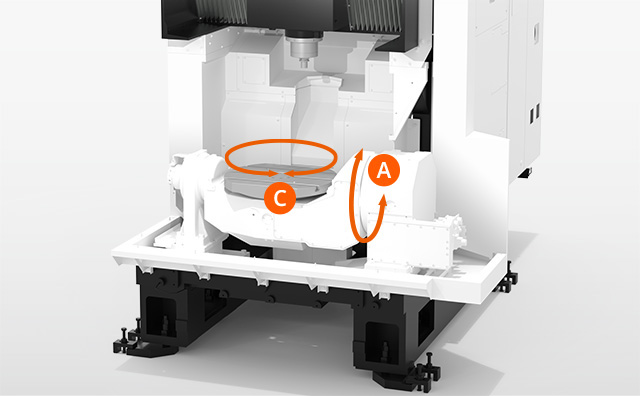

A- and C-axis table (FF-400V/30)

Equipped with a high-rigidity 2-axis rotary table(A-axis and C-axis) with support on both ends. Simultaneous 4-axis + A-axis indexing enables multi-surface continuous machining from any angle, achieving process integration.

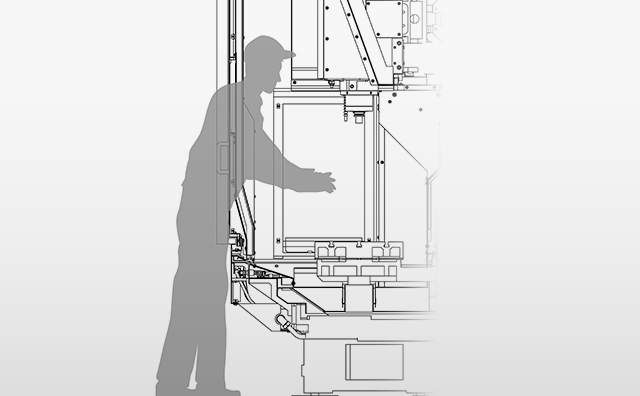

Ergonomic design for ease of operation

Wide opening and lightweight front door

The front door is designed for easy opening and closing to reduce the load on the operator when loading and unloading workpieces.

Excellent access to table and spindle

Workpiece loading / unloading, fixture changing, and checking the spindle tool can all be done in a natural posture. Standard cover coolant prevents the accumulation of chip, and centering conveyor structure discharges chip directly under the table, which reducing the workload of the operator.

High-speed and high-accuracy simultaneous 4-axis CNC system

MAZATROL SmoothEz

The digital setup function can replicate the machine of your factory in the PC at your office. On the machine side, operation programs can be created while checking the workpiece shape and process, intuitively with touch panel controls.

Reference Video

FF-400V/30 L

FF-400V/30

| Tool shank (standard) | BT30 |

| Max. spindle speed | 12000 min-1 (rpm) |

| Table size | Φ500 mm × 400 mm |