| Table size | 3500 mm × 820 mm |

| Tool shank (standard) | BT40 |

| Max. spindle speed | 18000 min-1 (rpm) |

| Max. workpiece size | Φ820 mm × 3690 mm |

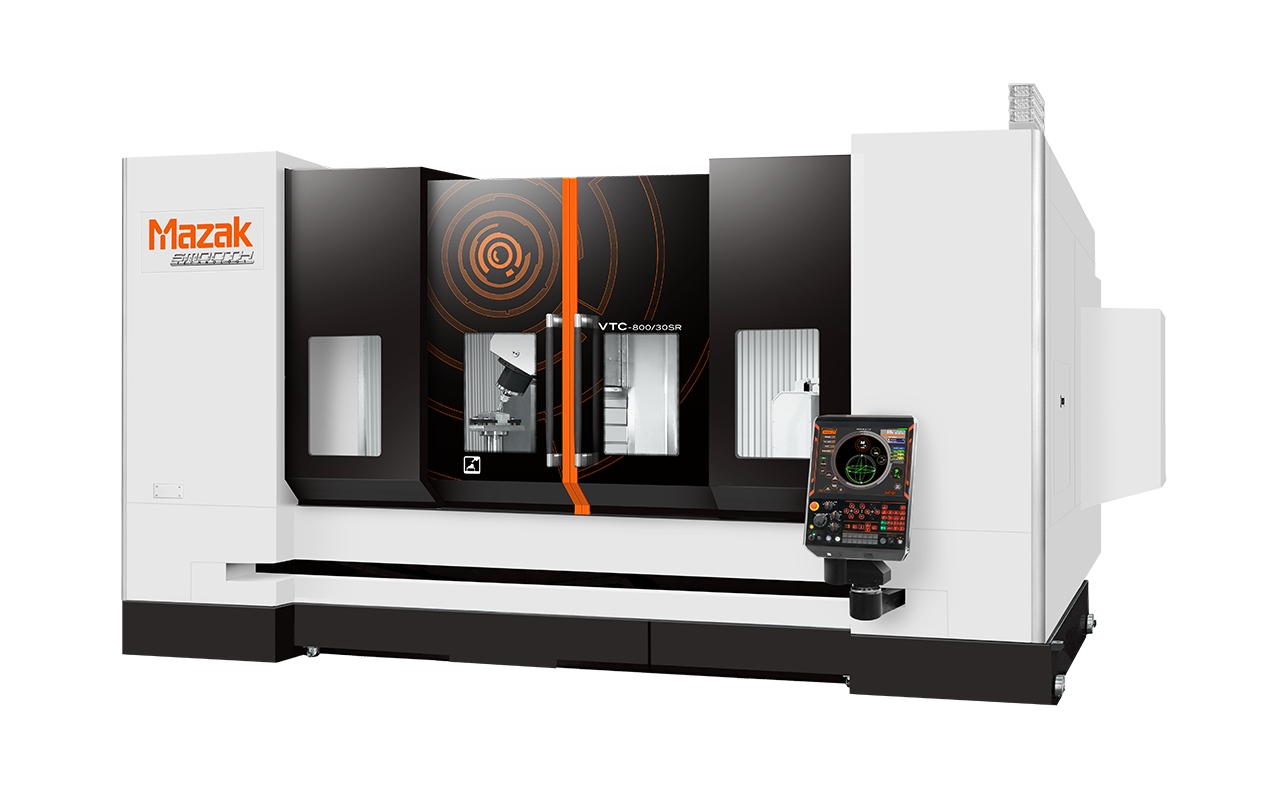

5-axis Machining Centers

VTC

- Machining of complex workpiece contours by simultaneous 5-axis machining*1

- Machining at any angle of vertical, horizontal, and slanted surfaces with ±110° B-axis swiveling head, increasing productivity through process integration.

- 3500 mm × 820 mm long table allows machining of long workpieces, multiple pieces, and can be used as a 2-pallet changer.*2

- 18000 min -1 high output spindle for machining a variety of materials from aluminum to steel

*1: VTC-800/30SR requires optional NC rotary table.

*2: Optional fixed table for VTC-800/30SDR has different dimensions.

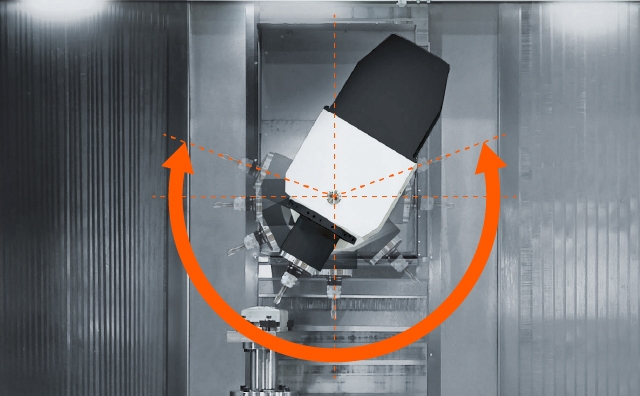

Swivel axis enables various machining

B-axis swiveling head

B-axis swiveling head with a swivel range of 220° performs indexing at 0.0001° increments with a zero backlash roller gear cam and servo motor.

Index coupling can be clamped every 5° increments and are suitable for heavy duty cutting.

In addition, any angle of vertical, horizontal, and slanted surfaces can be machined, improving productivity through process integration.

High-performance spindle for a variety of production requirements

The VTC-800/30 series has a 18000 min-1, 35 kW (47 HP) [50% ED] high output spindle.

The spindle can be used to cut various materials, including aluminum, cast iron, and steel.

Flexible working area for a wide range of machining

The 3000 mm X-axis stroke and the 800 mm Y-axis stroke are suitable for a variety of machining.

High speed operation

The advanced control system, servo motors, and roller guides maximize the capacity of the high-performance spindle and achieve the fastest rapid traverse rates and feedrates in its class. This reduces non-cutting time.

Rapid traverse rate (X-, Y-, Z-axis) 50000 mm/min

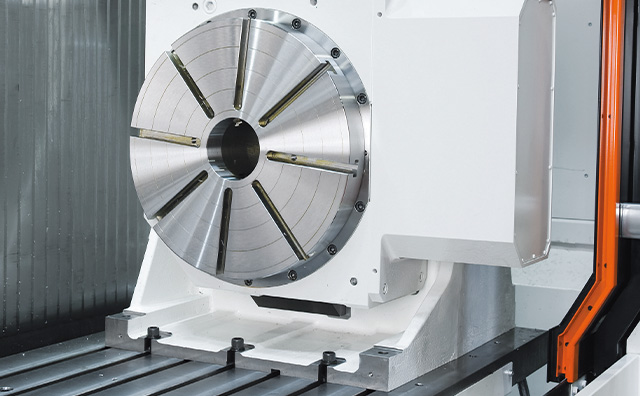

NC rotary table (option)*

Selecting the optional NC rotary table enables simultaneous 5-axis machining.

The rotary table, which can be placed horizontally or vertically, can also be placed on either side of the machine table.

The same roller gear cam as the B-axis allows contour machining.

* Compatible with VTC-800/30SR only

Removable center partition (option)*

By dividing the machining area with an optional center partition, one side can be machining while the other side is installing next workpiece, thereby increasing productivity.

Mounting the optional NC rotary table on both sides enables much higher-value machining.

* Compatible with VTC-800/30SR only

Dual synchronized rotary tables*

Ideal for machining long 5-axis workpieces such as air craft parts

The VTC-800/30SDR has a dual synchronized rotary tables and, by eliminating the fixed table, a highly effective chip disposal.

This is an ideal solution for machining aerospace components which require high-accuracy simultaneous 5-axis machining and high material removal rates.

* Compatible with VTC-800/30SDR only

Applications

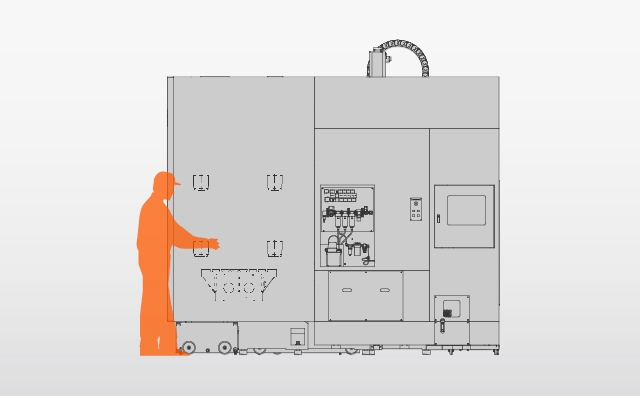

Ergonomic design for convenient operation

Excellent table access

The door is sashless, without any beams in the ceiling area. There is no interference when using an overhead crane for fixture setup and loading/unloading of large workpieces.

Large windows

The large front door windows as standard allow the operator to easily monitor the machining process.

Accessibility

The operator door provides excellent accessibility to the table, making setup easier.