Marine

The range of different components required by the marine sector places huge demands on its suppliers. We examine the machining challenges faced by suppliers to the sector and offer some solutions.

The marine sector is exceptionally diverse, encompassing everything from shipbuilding and repair through to yachting. The range of components demanded are wide and made from a huge variety of metals, including aluminium, cobalt, stainless steel, titanium, bronze and CFRP.

Mazak has a long track record of delivering machine tools for these types of manufacturing, and offers machine models and machining applications for a wide variety of small-quantity and variable-volume production. Particularly in the machining of parts using large vertical and horizontal multi-tasking machines, process integration reduces the number of operators, set-ups and the movement of large components around a machine shop and improves the quality of the final product. It also contributes to improved profitability through significantly shorter lead times and cost reductions.

Applications

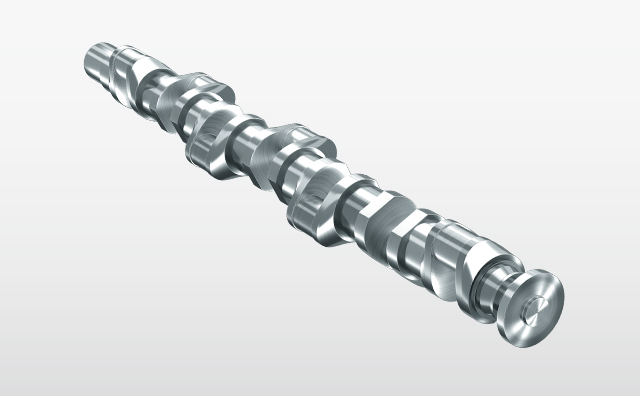

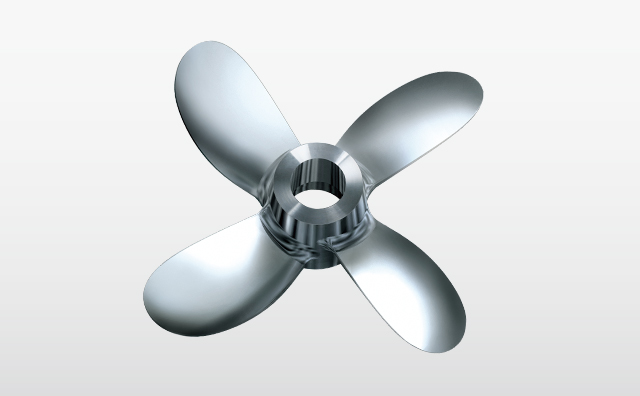

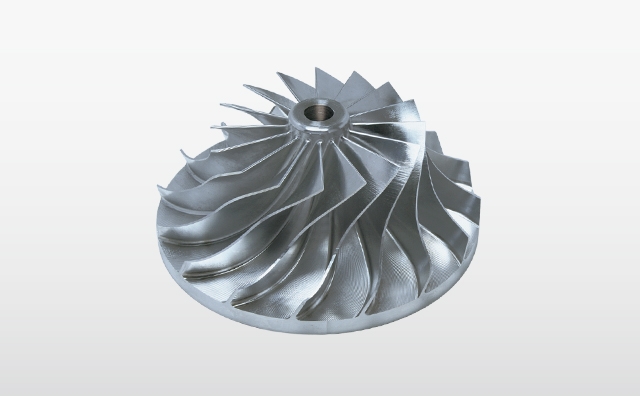

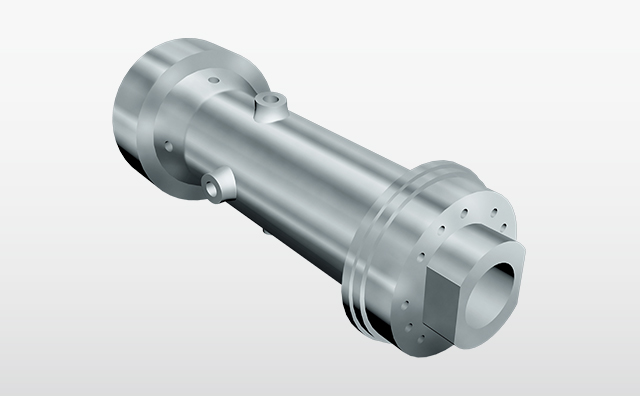

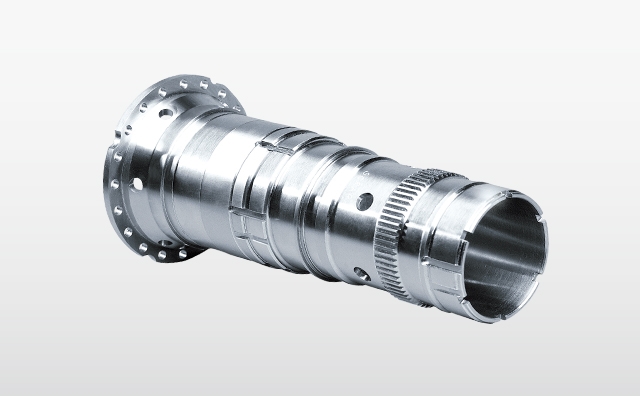

Mazak's machine tools are capable of machining parts with complex shapes and a variety of materials, shortening manufacturing lead times, providing consistent quality, and improving productivity.

Mazak's machine tools are used to manufacture various marine parts

QUICK TURN Series

High-performance CNC turning center

Turning, milling, Y-axis and second spindle specifications designed to meet your production requirements

SLANT TURN Series

CNC turning center

Powerful cutting of large and long workpieces with high torque spindles

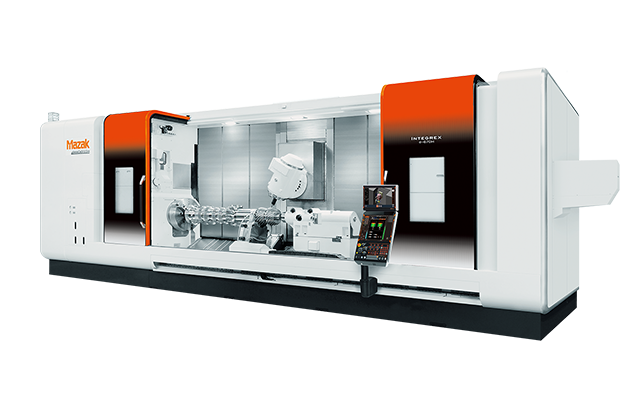

INTEGREX i-H Series

INTEGREX i-H Series

Simultaneous 5-axis horizontal multi-tasking machine

From turning to 5-axis machining using the Y- and B-axis, this single machine integrates multiple processes

INTEGREX e-H Series

Horizontal multi-tasking machine for long and large workpieces

Large swing and Y-axis stroke for large workpieces, high-power turning spindle and mill spindle

MEGA TURN Series

Vertical CNC turning center

Highly efficient machining of large cylindrical parts; two machines can be arranged, a standard machine and a symmetrical machine

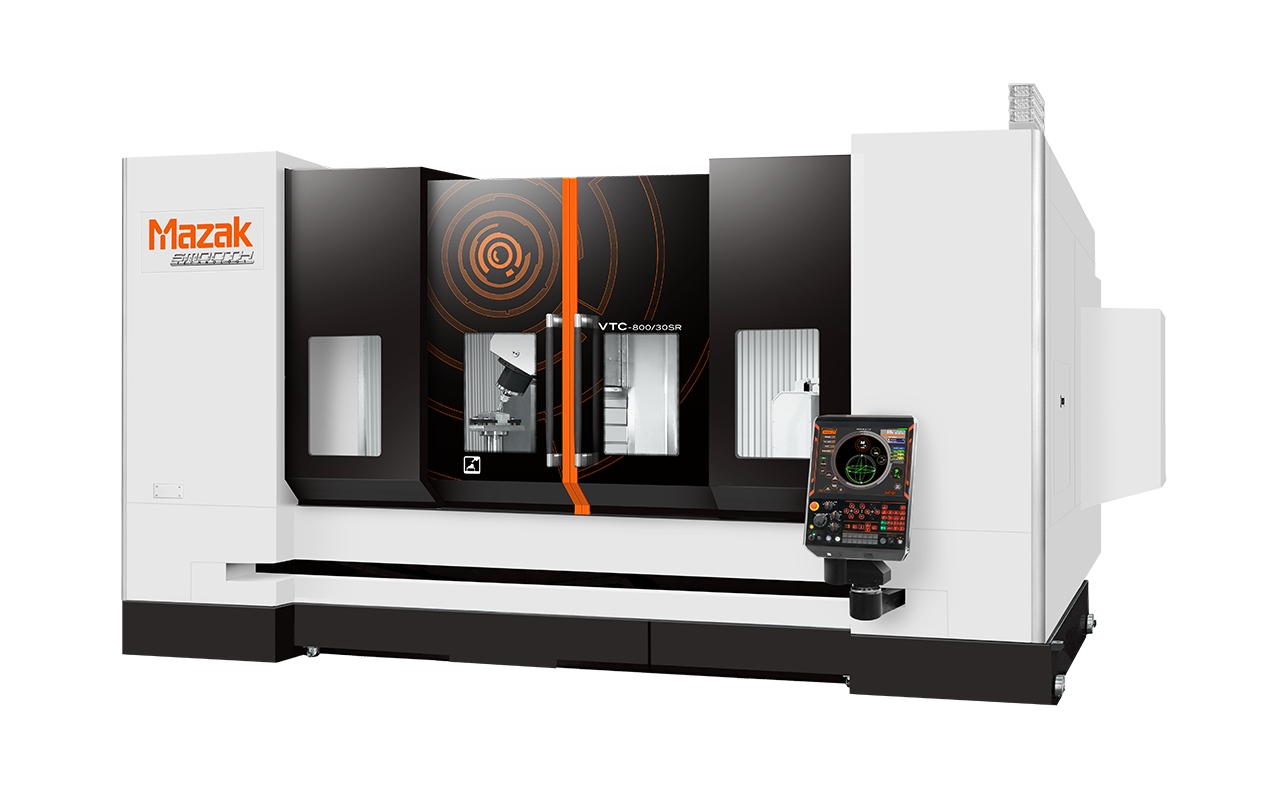

VTC Series

Travelling column type 5-axis machining center

Fixed table for large and long workpieces, B-axis swiveling head

VARIAXIS i NEO Series

Simultaneous 5-axis vertical machining center

High performance machine tool NEO series with high productivity and environmental performance

INTEGREX e-V Series

Simultaneous 5-axis double-column machining center suitable for large workpieces

High-accurate multi-tasking machine capable of 5-axis machining, multi-surface machining and turning of marine propellers and other components