Job Shop

Parts machining in job shops is required in a wide range of industries, which constantly demand high machining quality, reduced costs and short delivery times. In order to process a wide variety of parts with fewer man-hours and lower costs, it is necessary to propose the most suitable machine tools, machining technology and tools for the customer's production system. In recent years, more and more customers have adopted robots and automation systems in response to labour shortages and productivity improvements. Mazak offers a wide range of 5-axis and multi-tasking machines that reduce lead times through process integration, as well as a large number of machine tool lines for different workpiece sizes, materials and shapes. Furthermore, these machine tools can be flexibly linked to robots and automation systems, so that they can operate continuously without personnel at night and on weekends and holidays, which has the effect of significantly reducing production costs. Mazak provides total support for the automation of factory equipment, from production start-up and operation to service and maintenance.

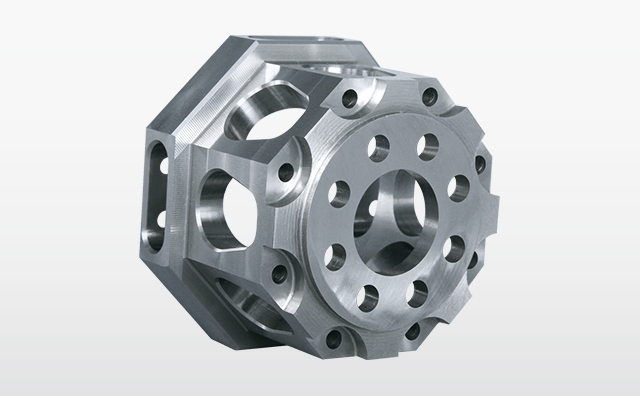

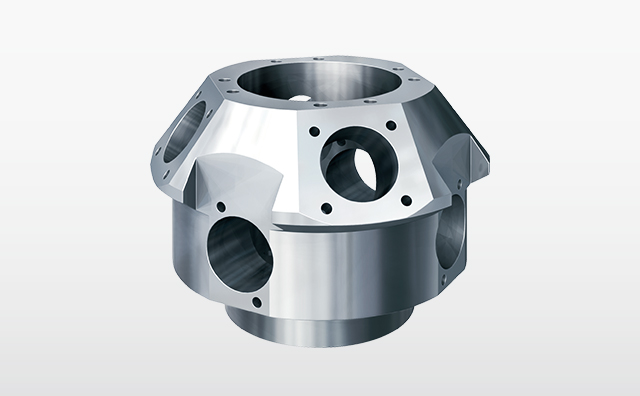

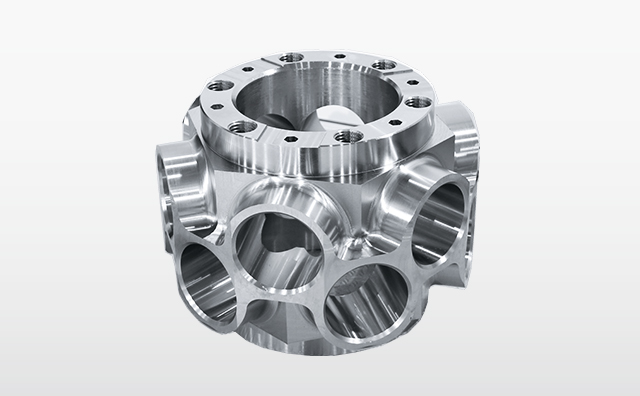

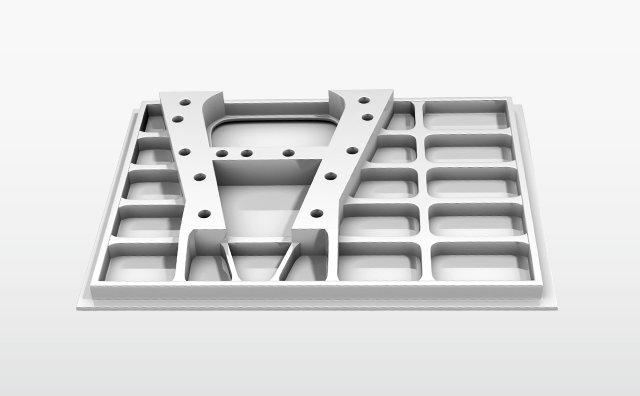

Applications

Various Mazak machine tools are used in job shops

QUICK TURN Series

High-performance CNC turning center

Turning, milling, Y-axis and second spindle specifications designed to meet your production requirements

SLANT TURN Series

Large CNC turning center

Highly productive CNC turing center with large spindle bore diameter, reducing turning cycle times for long shaft workpieces

MEGA TURN Series

Vertical CNC turning center

Highly efficient machining of large cylindrical parts; two machines can be arranged, a standard machine and a symmetrical machine

INTEGREX i-H Series

Simultaneous 5-axis horizontal multi-tasking machine

From turning to 5-axis machining using the Y- and B-axis, this single machine integrates multiple processes

VTC Series

Traveling column type vertical machining center

Fixed long table can be flexibly used for machining long workpieces in a small floor space

VARIAXIS i NEO Series

Simultaneous 5-axis Vertical Machining Center

The high-performance NEO series with high productivity and low environmental impact technologies

HCN Series

Horizontal machining center

A wide range of spindle variations and a highly rigid structure for highly efficient machining

HCN NEO Series

High-speed, high-precision horizontal machining center

High performance machine tool NEO series with high productivity and environmental performance

INTEGREX j Series

Entry model multi-tasking machine

From turning to multi-surface machining using the Y- and B-axis, this single machine integrates multiple processes