Intech - we tech care

We tech care

Supporting the medical industry involves more than just doctors and nurses. Indeed, the medical equipment used in the field is crucial to delivering patient care. Intech, the French orthopedic instrument manufacturer provides its services to medical device companies worldwide and supports the industry with an advanced machining platform.

A global company for healthcare

The advancement of science has been pushing the boundaries of medical care and minimally invasive surgery. Enter Intech, a market leader and game-changer for orthopedics, headquartered in France. The group specializes in the manufacturing of medical devices from implants to surgical ancillaries and handles everything from design to machining and packaging, with a particular focus on complex instrumentation.

There were only 17 employees when the company was founded in 2000. Over the years, Intech gradually grew its footprint by expanding overseas to the United States and Malaysia while building out its offering to provide its customers with end-to-end solutions.

Today, the company has grown into a global corporation that counts over 1,200 “Intechers” across nine factories in Europe, the United States, and Asia, providing medical equipment worldwide.

As it strives to establish itself as “the partner of choice for medical device contract-manufacturing”, the company is praised for its strong R&D and manufacturing expertise.

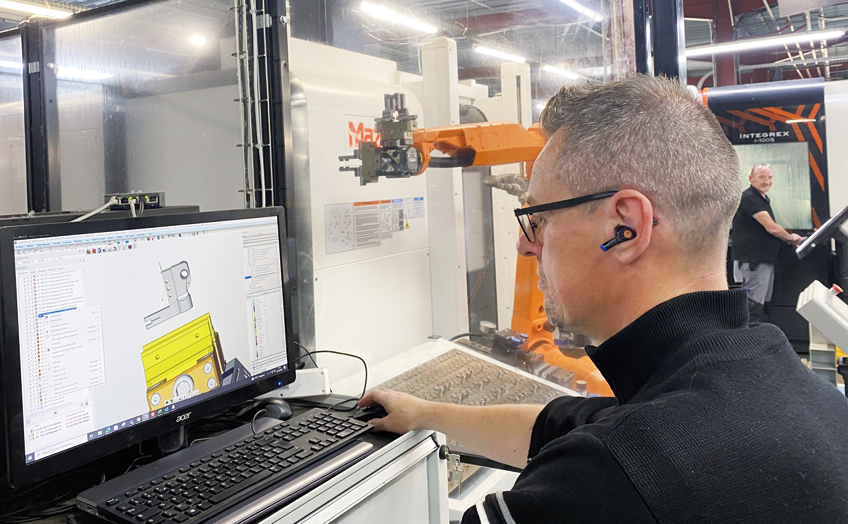

More than 50 Mazak machines at one site

Intech counts over 100 pieces of Mazak equipment within the group but one site stands out: a facility formerly known as Turner Machine that is based in Athens, Alabama (USA).

That facility joined the group in 2015 but had purchased its first Mazak machine back in 1985: a QUICK TURN 25 2-axis lathe as it established itself as a tool and die shop.

The affordability and excellent precision in machining were the driving factors behind its adoption. And, more than 40 years later, their relationship with Mazak is stronger than ever!

Intech Athens boasts a 10,000 square meter (100,000 square foot) facility including a robust production area with over 70 CNC machines, 57 of which are Mazak equipment including lathes, machining centers, 5-axis multitasking machines and automation systems, which occupy a central role in the machining of complex components that go into minimally-invasive implants and instruments.

Intech’s commitment to innovation and investment in new technologies is paying off – this site has more than doubled its revenue since it joined the Intech group in 2015!

"Arguably, the INTEGREX i-H series has had the most impact within our high mix, low volume operations by improving efficiency with complete multi-axis machining in one operation that took 2 or 3 previously”, said Mr. Joseph Forsyth – Director of Advanced Manufacturing at Intech Athens.

He also pointed out that leveraging Mazak’s smart automation solution has “increased opening time”, and that the higher responsiveness from the MAZATROL Smooth CNC systems has allows them to “improve cycle times”.

Better products for a better life

Medical devices are becoming more and more intricate for improved care and faster patient recovery. To meet these needs, Intech is always at the forefront of new technologies.

They recently expanded their capabilities by joining forces with Lenkbar in Naples, Florida (USA) to offer in-house grinding, in a merger that is poised to advance minimally invasive surgery, cutting tools, and sports medicine.

"At Intech, we blend INtelligence with TECHnology to create an entire ecosystem of innovations. Drawing on our synergies to reach higher and rise to the challenge with passion, ambition and humility. Forever exceeding expectations to deliver a world of excellence to enhance patients' lives.”, said Mr. Laurent Pruvost, President & CEO of Intech.

"Mazak has been a true aftermarket partner to all of our sites by being responsive for maintenance and servicing of equipment. This helps us reduce the non-forecasted downtime ensuring that Intech is back up and running in a short window and can continue producing devices that help improve patient care.”

Today, Intech takes pride in delivering precision machining on a global scale which inevitably helps improve patients’ lives worldwide.

Intech

| President & CEO | Laurent Pruvost |

| Head Office | 158 rue de l'Eglise, 62180 Rang du Fliers, France |

| Number of employees | 1,200 |