Utilizing AI and digital technology

AI and digital technology enable the optimization of the machining condition for higher accuracy and digital setup / management. With these technologies, electrical power consumption can be reduced.

Ai Thermal Shield leads to energy saving

The Ai Thermal Shield achieves a stable continuous machining accuracy by precisely controlling the machine in response to the change of the machining environment . By accumulating and deep-learning from the data acquired after the processing of parts, each machine can compensate itself according to its unique characteristics. Stable machining accuracy eliminates reprocessing due to machining failure and reduces electrical power consumption for temperature control as well.

- Image-1

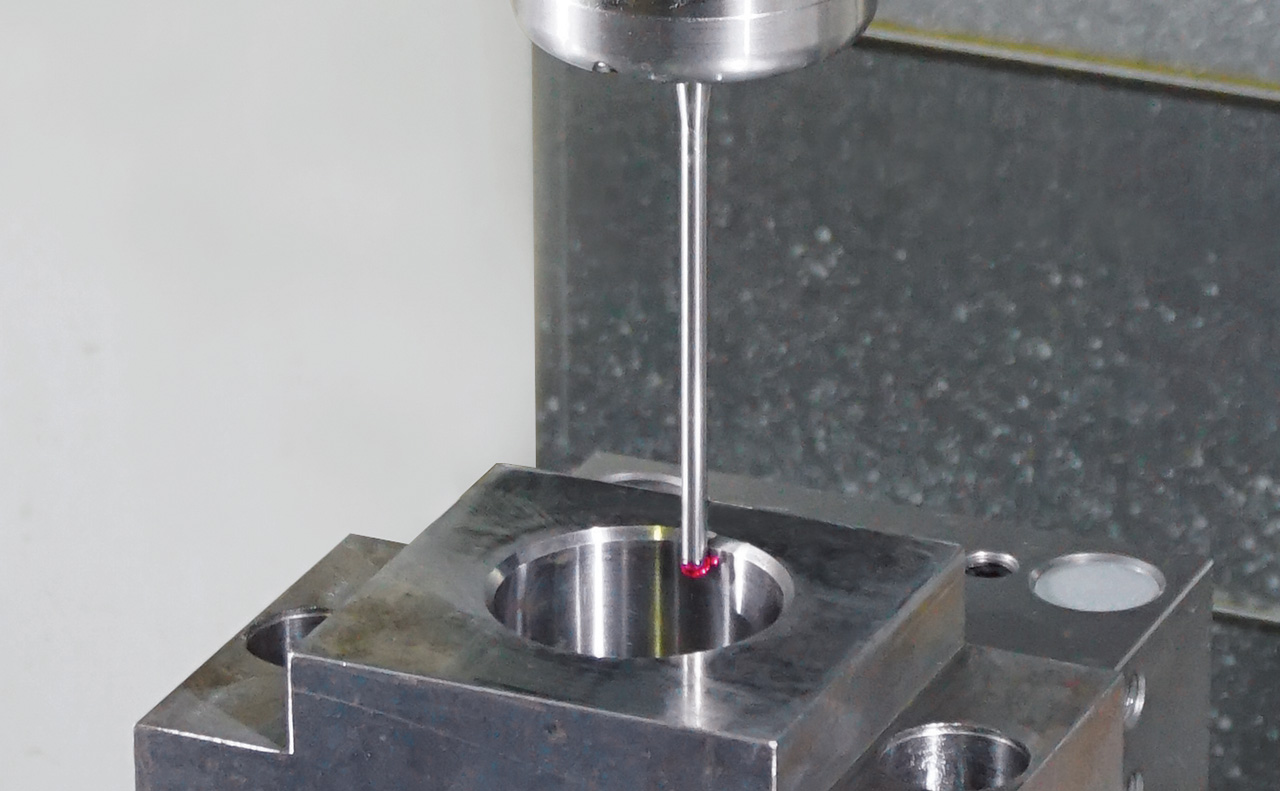

- Image-2

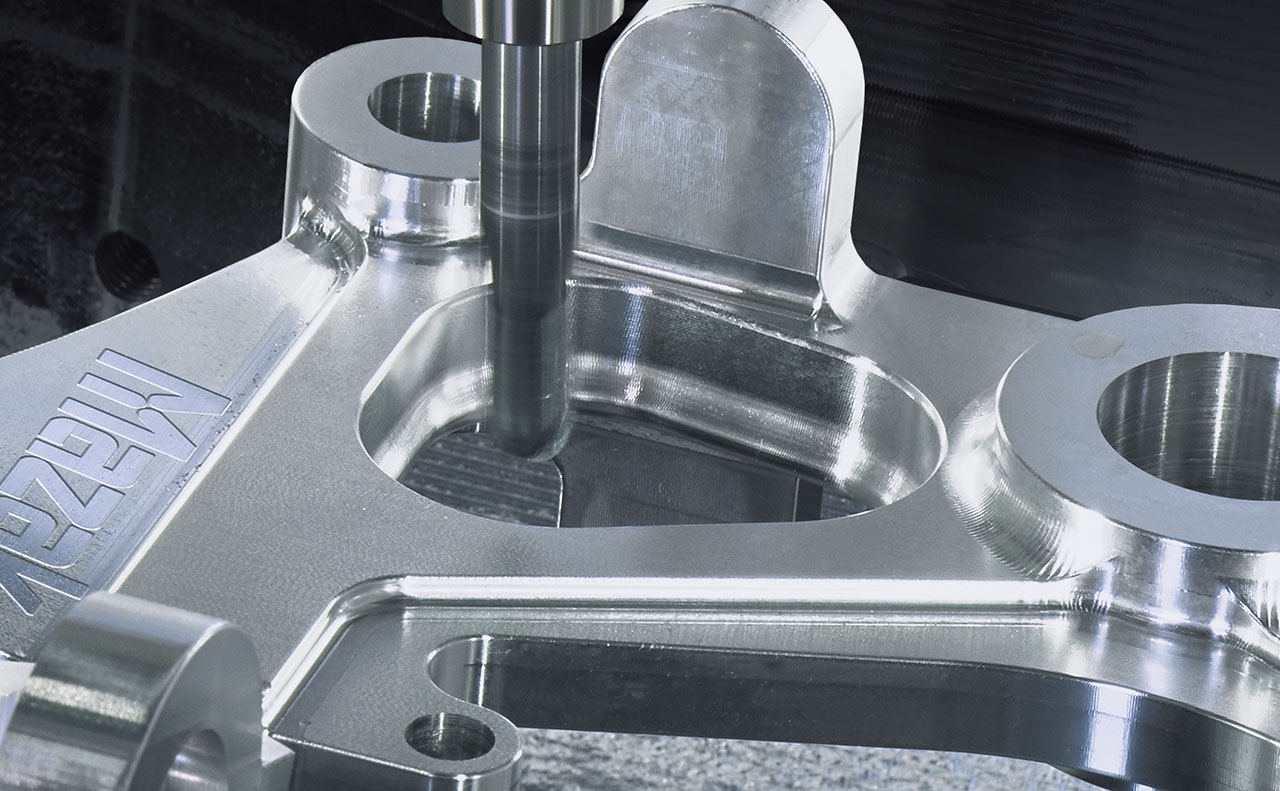

- Image-3

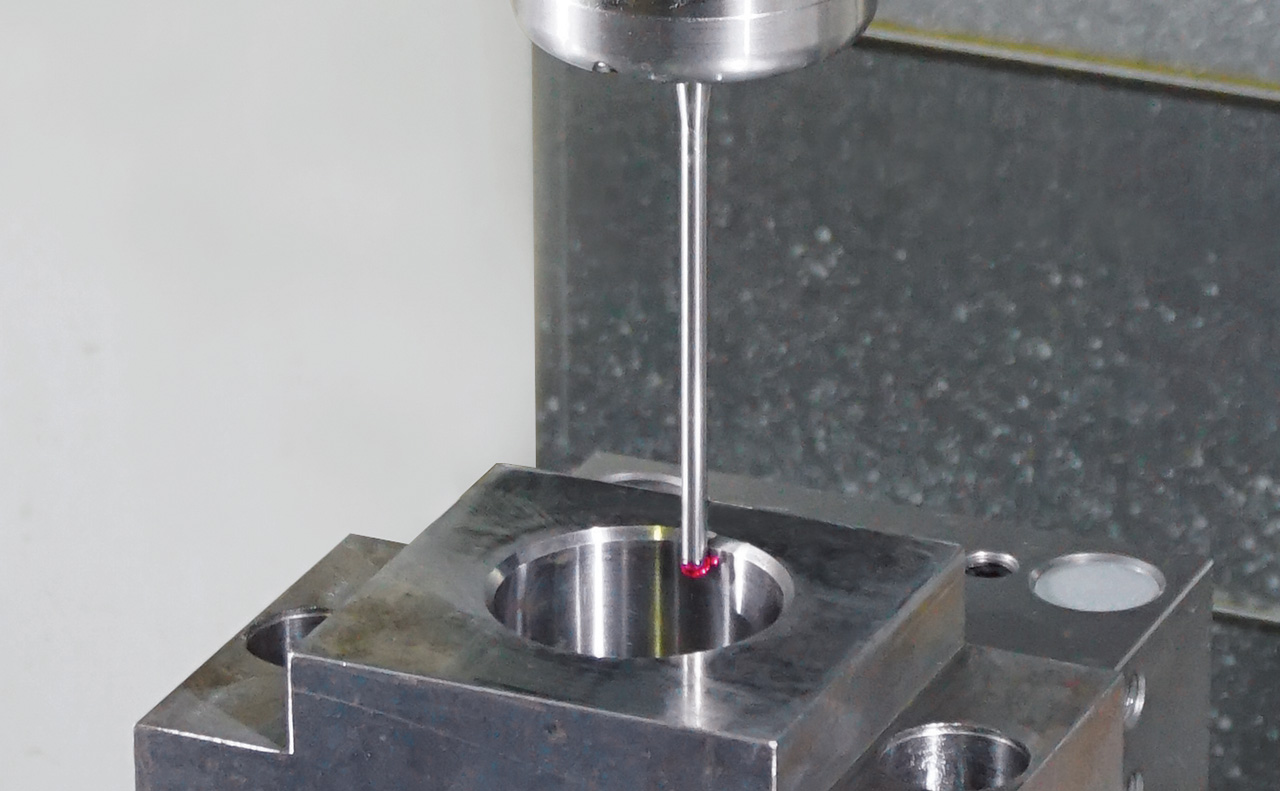

- Image-4

Reduction of power consumption with digital setup

Digital setup utilizing digital twin technology creates a virtual machine on your office PC for efficient setup and improved productivity. As you can build a virtual machine tool on the office computer and operate setup as you can on the actual machine, operation time on the actual machine can be minimized, contributing to the reduction of electrical power consumption and achieving a higher operating rate.