| Pallet size | Φ500 mm × 400 mm |

| Tool shank (standard) | BIG-PLUS No.40 |

| Max. spindle speed | 12000 min-1 (rpm) |

| Max. workpiece size | Φ500 mm × 350 mm |

5-Axis Machining Centers

VARIAXIS j

- A rigid trunnion table design supports tables on both sides for heavy-duty machining. High-accuracy machining is possible

- 0.0001° indexing increment for a variety of multiple-surface machining (simultaneous 4-axis + A-axis indexing) [j-500]

- Simultaneous 5-axis control for 3-dimensional curved surface machining [j-500/5X]

- Excellent accessibility to the table and magazine in front of the machine for easier operation

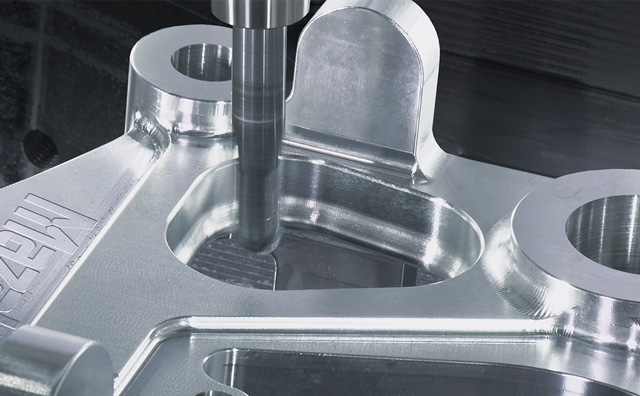

Machine structure for high-accuracy machining

1: Linear roller guides utilized on the X-, Y- and Z-axis

The linear roller guides on the X-, Y- and Z-axis utilized by the VARIAXIS j series provide high-accuracy positioning.

Additionally, with their high rigidity and considerably lower friction, high-speed feed rates can be used over a wide range of machining, from heavy-duty to high-speed cutting.

2: High rigidity table

High rigidity tilting rotary table for high-speed and high-accuracy machining.

3: Rotary axis equipped with roller gear cams

The VARIAXIS j series tilt and rotary tables use roller gear cams for superior accuracy, rigidity, and durability. Elimination of backlash ensures high-accuracy and high-efficiency machining.

Axis configurations designed for various multiple-surface machining and 5-axis machining

Multi-surface machining: VARIAXIS j-500

(CNC: MAZATROL SmoothG)

Simultaneous 5-axis machining: VARIAXIS j-500/5X

(CNC: MAZATROL SmoothAi)

High-rigidity, high-speed spindle for a wide variety of materials

Standard spindle

| maximum spindle speed | 12000 min-1 (rpm) |

| Output [40% ED] | 11 kW (15 HP) |

| Torque [40% ED] | 65.1 N・m |

High speed spindle (Optional)

| Max. spindle speed | 18000 min-1 (rpm) |

| Output [40% ED] | 15 kW (20 HP) |

| Torque [40% ED] | 59.7 N・m |

Applications

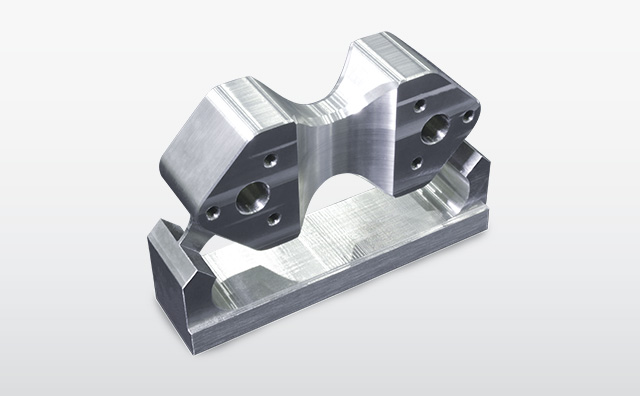

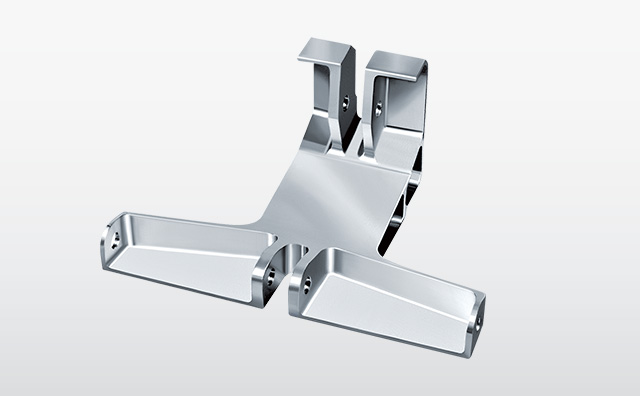

Aerospace component

Fastener

Food logistics component

Bracket

General industry component

Blower

Automotive component

Control arm

Stable machining accuracy over long periods of operation

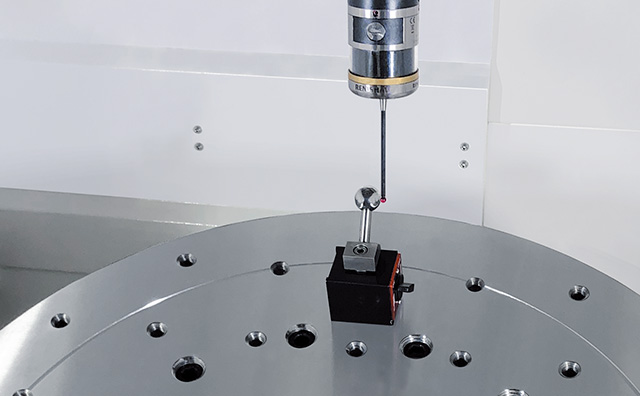

High-Accuracy 5-axis Calibration MAZA-CHECK

Position misalignment and incline of the rotary axis can automatically be measured and compensated to realize high-accuracy 5-axis machining.

In addition to offsetting the position deviation traveling parallel to the linear axis, angular deviation due to tilt direction can also be corrected.

- *Wireless touch probe RMP600 is optional equipment.

- *Optional function for VARIAXIS j-500.

Ai Thermal Shield

Based on the spindle speed and temperature of the machine, Ai Thermal Shield suppresses changes in the cutting edge position. It stabilizes continuous machining accuracy through meticulous machine control that takes into account temperature changes, machine position, coolant ON/OFF, and other factors. Furthermore, by accumulating and learning data from subsequent measurements, thermal displacement compensation can be optimized for each machining environment.

- machining

- Workpiece Measurement

- Optimization Simulation

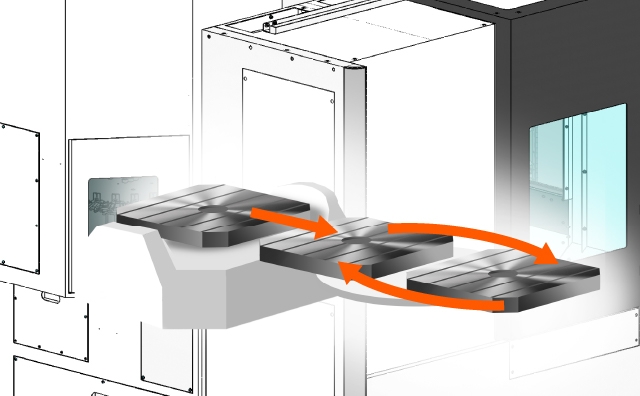

2-pallet changer (Optional)

The VARIAXIS j series offers the 2-pallet changer as an option.

The next workpiece can be setup during the machining of the current workpiece for higher productivity.

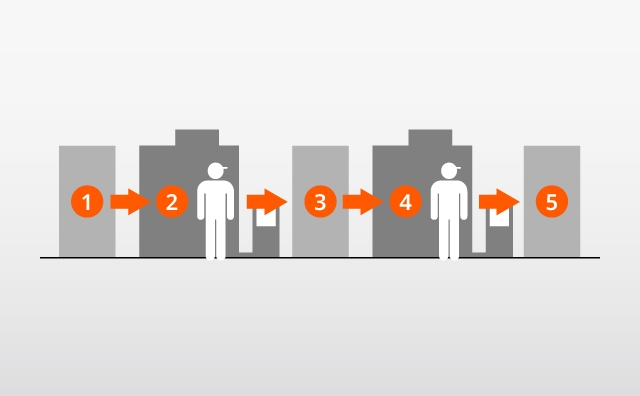

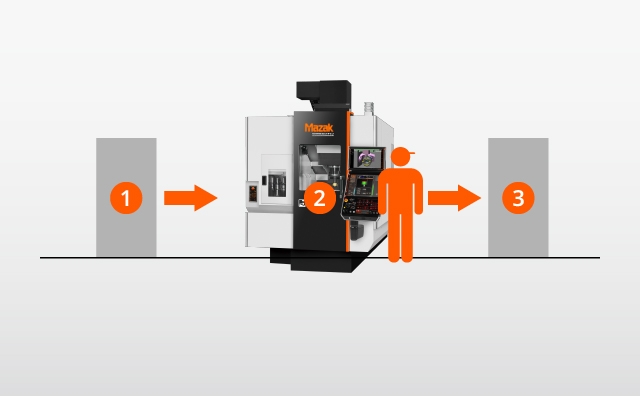

Large reduction of total production time

The VARIAXIS j-500 series incorporates all machining processes from raw material input through final machining – in just one machine. It provides the ability to reduce production lead time, improve machining accuracy, reduce floor space and initial cost, lower operating expenses, reduce operator requirements, and to improve the work environment. As a result, it not only streamlines production, it also improves overall management.

Previous production method

Horizontal machining centers × 2

Fixtures and tools × 2

Operator × 2

Large in-process inventory/in-process time

VARIAXIS j-500

VARIAXIS j-500 × 1

Fixtures and tools × 1

Operator × 1

Small in-process inventory/in-process time