Additive Manufacturing

VC-500A/5X AM HWD

- 5-axis HOT WIRE Deposition additive head deposits 3-4 lbs/hour to help achieve 98% material utilization rate

- Easy-to-use MAZATROL SmoothX CNC for high-speed, high-accuracy performance with both EIA/ISO and conversational programming capabilities

- 5-axis rotary/tilt trunnion table with roller gear cam technology

Part-processing capabilities beyond those of conventional Multi-Tasking

Reduce lead times and costs

Designed and built in Kentucky, the VC-500A/5X AM HWD offers manufacturers part-processing capabilities beyond those of conventional Multi-Tasking to reduce lead times and part costs, increase machining accuracy, improve part quality and achieve even higher levels of productivity, flexibility and profitability.

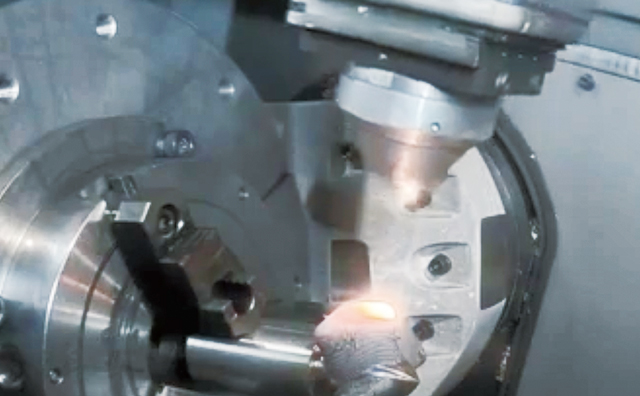

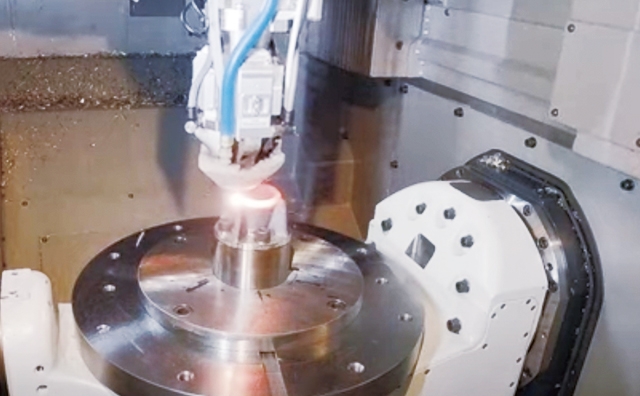

HOT WIRE Deposition technology

Precisely melt metal wire directly on to a base material

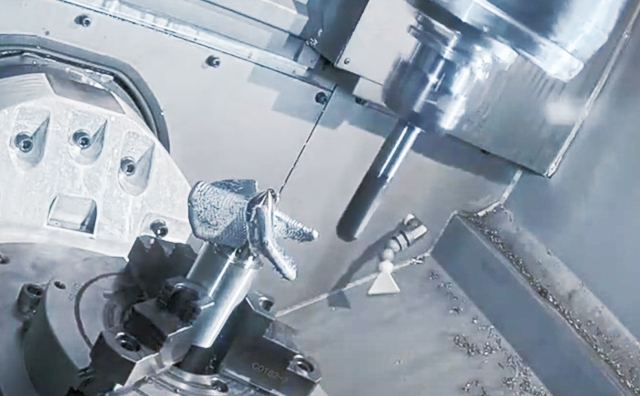

The VC-500A/5X AM HWD incorporates the new and innovative HOT WIRE Deposition technology, an additive manufacturing technique that Mazak developed in collaboration with Lincoln Electric. Unlike conventional welding, the HWD head uses both an arc torch and laser to precisely melt metal wire directly on to a base material and/or part at a rate of three to four pounds per hour. The two materials – wire and workpiece – can be dissimilar, which allows shops to generate exceptionally precise sealing coatings along with near-net shape part features. The machine may also be used to repair costly complex components such as impellers and turbine blades along with tool and die parts.

On its milling side, the VC-500A/5X AM HWD comes standard equipped with a robust, high-performance CAT No. 40, 12000 rpm spindle that delivers exceptional metal removal capabilities in all common materials, including steel, aluminum and cast iron.

An ample 30-tool storage magazine ensures continuous uninterrupted part machining, as does the machine’s compact chip conveyor and mist collector with smoke filter.

Machine Characteristics

- 5-axis HOT WIRE Deposition additive head deposits 3-4 lbs / hour to help achieve 98 % material utilization rate

- Easy-to-use MAZATROL SmoothX CNC for high-speed, high-accuracy performance with both EIA/ISO and conversational programming capabilities

- 5-axis rotary / tilt trunnion table with roller gear cam technology

- Rigid, powerful spindle comes in various maximum speed options

- MX Hybrid Roller Guide System offers rigidity, speed and accuracy

- 30 or 60-tool magazine with an automatic tool changer

- Simple and efficient chip management helps reduce downtime

- Small footprint and easy installation

Machine Specifications

Capacity | Max. Workpiece Diameter | 19.6" / 500 mm |

Max. Workpiece Height | 12" / 305 mm | |

Spindle | Spindle connection | 40 |

Max. Speed | 12000 rpm | |

Motor Output (10 min. rating) | 25 HP / 19 kW | |

Magazine | Number of Tools | 30 / 60 (optional) |

Rotary Axis | Spindle Tilt (B-axis) | ± 110 degrees |

Table indexing (C-axis) | 360000 | |

Strokes / Travels | X-axis | 21.85" / 555 mm |

Y-axis | 19.88" / 50 mm | |

Z-axis | 20.08" / 510 mm |